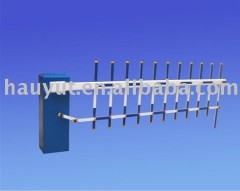

barrier gate

| Min. Order: | 1 Set/Sets |

|---|---|

| Place of Origin: | Beijing |

Company Profile

| Location: | Beijing, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | HYT D07 |

|---|---|

| Brand Name: | hauyut |

Product Description

Electrical characteristics

1. The system will never halt because it is controlled by the MUC combining software trap and hardware watchdog.

2. Abrasion and deviation will never happen because it is a kind of non-contact work adopting a magnetic induction Hall device to control the whole distance.

3. The technologies of photoelectric coupling, non-contacting and passing zero trigger guarantee the main control panel sparkles and clear to work in a highly reliable way.

4. The protection for overtime ascending and descending operation and overheating motors can effectively prevent the electric brake from abnormal break-down.

5. The button of machinery process operation is used to protect the whole system in case of sudden power outage.

6. The broad range of single-phase power input (160V-260V) well suits the bad environment of toll gates on wild roads.

7.The optically isolated SPI and the over-1500 V isolation voltage lend the up-level computer a secure work condition so that a highly reliable communication resisting vehicle sparks and high EMI can be realized.

Major functions

1. Ascending, descending and stop operations can be controlled by the manual button.

2. In addition to ascending, descending and stop operations, the the wireless remote can enable locking and unlocking for the manual button. 3. The botton can be unlocked automatically and the bar can be uplifted manually when the power is off.

4. An easy-to-maintain and easy-to-debug self-checking mode is provided.

5. An optional vehicle sensor can be installed to enable automatic bar dropping, uplifting and prevention of vehicle tamping.

6. It is available to use the top and two pairs of traffic lights on both sides specially designed for toll.

7. An optically isolated long-line driver can be connected to the RS232-C SPI interface of the PC, which enables abundance of instruction on bottom control and state return to guarantee full control by toll system computer over the electric brake.

8. Other functions can be added on demand.

.jpg)