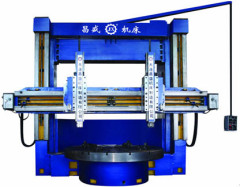

CK5225 CNC Double Column Vertical Lathe

190000.0~220000.0 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 40 PCS per month |

| Place of Origin: | Liaoning |

Company Profile

| Location: | Dalian, Liaoning, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Vertical Lathe, Metal Tools, Lathe Tools, Heavy Lathe, Cnc Lathe Machine |

Product Detail

| Model No.: | CK5225 |

|---|---|

| Means of Transport: | Ocean |

| Color: | Blue |

| Material: | High grade cast iron |

| Installatiom: | Offer technical support |

| Production Capacity: | 40 PCS per month |

| Packing: | seworthy packing |

| Delivery Date: | 3-4 months |

Product Description

Description:

Being universal and heavy-type CNC double-column vertical lathe, the lathe is suitable for high-speed steel and hard alloy cutter, rough and fine turning processing of inner and outer cylindrical surface, conical surface, plane, all kinds of rotary surface and grooving of ferrous metals, nonferrous metals and some non-metallic parts.

Main structure:

1.Structure type: The lathe is of gantry type structure. The left and right stand column, articulated beam and other large parts are made from high strength, low stress HT250 cast iron. The hardness is HB170-190.

2.Workbench: The workbench adopts hydrostatic guideway.

3.Bearing: Radial axis of the bearing adopts high-precision NN30(D step) bearing. It had high precision, strong bearing capacity.

4.Beam: To ensure the accuracy of the machine, the beam is made from high strength, low stress HT300 cast iron. To extend the life of the machine, the contact surface of beam and stand column guideway is made of wearable Zn-Al alloy plates.

5.Rail head: The axis making level and vertical movement is drove by independent AC servo motor. The AC servo motor of vertical movement adopts ball screw transmission, improving the transmission efficiency of any axis.

6.Speed changing box: The material of gears is of high-frequency quenching handling of high quality alloy steel. The hardness can reach HRC45-50, the accuracy can reach 7 series. The speed changing box is of vertical type and not easy to beat teeth.

7.Hydraulic system: The hydraulic station has blocking, flow and pressure protection, the machine will stop working automatically if it is beyond the reach of operating requirements.

8.Numerical control system: Standard Siemens 802D system, matched DC main axis drive and AC feeding drive.

Specifications:

Name | Unit | CK5225 | Name | Unit | CK5225 |

Max cutting diameter of workpiece | mm | 2500 | Cutter feeding scope | mm/min | 0.12~145 |

Workbench diameter | mm | 2250 | Rapid movement speed of knife rest | mm/min | 2400 |

Max height of workpiece | mm | 1600/2000 | Beam movement speed | mm/min | 350 |

Max weight of workpiece | t | 15 | Turning angle of vertical slide | ° | ±30 |

Workbench speed range | r/min | 2~63 | Knife carrier size | mm | 40*50 |

Workbench speed series | step | two gears no step | Main motor power | kw | DC55 |

Max cutting force of right knife rest | kn | 35 | Machine dimensions(L*W*H) | mm | 5180*5200*4870 |

Max cutting force of left knife rest | kn | 30 | Machine weight | t | 33 |

Max workbench torque | kn.m | 63 |

Accessory (subject to the factory packing list):

chuck jaw, toolholder, Jack catch wrench, wrench, adjustment mat iron, footing screw.

After-sale service:

1.The full machine warranty is 1 year.

2.If there is something wrong with the lathe, the after-sale service personnel will reach the buyer within the specified time to determine fault, and remove it.

Main export markets:

Albania, Saudi Arabia, Indonesia, Iran, Brazil, Ukraine, Paraguay, Egypt

ISO9001 & CE