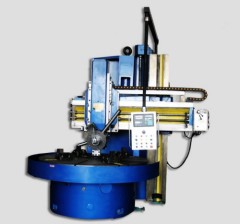

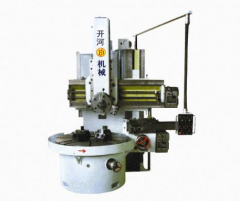

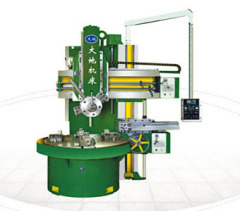

CK5112 CNC Single Column Vertical Lathe

80000.0~90000.0 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 40 PCS per month |

| Place of Origin: | Liaoning |

Company Profile

| Location: | Dalian, Liaoning, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Vertical Lathe, Metal Tools, Lathe Tools, Heavy Lathe, Cnc Lathe Machine |

Product Detail

| Model No.: | CK5112 |

|---|---|

| Means of Transport: | Ocean |

| Color: | Blue |

| Material: | High grade cast iron |

| Installation: | Offer technical support |

| Production Capacity: | 40 PCS per month |

| Packing: | Seaworthy Packing |

| Delivery Date: | 2-3 month |

Product Description

Description:

CK5112 lathe is CNC single-column vertical lathe aimed at processing inner round and outer round of large workpiece and plane. The lathe is suitable for high-speed steel and hard alloy steel cutter, processing black metal, non-ferrous metal and some non-metallic materials. The following process can be finished with the lathe: rough and fine turning of the inner and outer cylinder, plane and conical surface, grooving, severing and simple surface.

Main structure:

1.Stand column:

The stand columns are divided into two main and auxiliary rails at left and right. The machine can be more stable at run time, more rigid when strong cutting because the span between the main and the auxiliary guide rail becomes large and 55 degrees forked tail on one side of the main rail can be oriented.

2. The main drive system:

The main transmission gets power from 30KW three-phase asynchronous machine or continuous current dynamo. From belt to gear box, through two grades infinitely variable speeds, then the spiral bevel gear changes 90 degrees, the skewed tooth put the gear ring and the worktable into rotation. The wheel gear in the gear box quenching, grinding, gets high transmission accuracy and transmission efficiency, and reduces transmission vibration and noise.

3.Workbench part:

The workbench part is constituted by the workbench, the main spindle and the workbench base.The worktable rotation and load-bearing consist of hydrostatic slideway and two sets of 3,182,100 series bearings. The workbench embeds with zinc, aluminum and copper alloy guide rail board. Artificial scraping carefully can ensure the verticality with the main spindle, thus reducing the nonuniformity of shearing the oil film when rotating, ensuring the long-term stability of the lathe rotation accuracy.

4.Beam:

The ball screw, planetary reducer, servo motor in the crossbar constitute the left and right feeding system. The movement of the beam in the column is oriented by 55 degrees guide rail and platen.

5. Vertical Turret:

Vertical turret is composited with the rotary slide, ram, ball screw, planetary gear and servo motor. All sliding contact surfaces of the vertical turret are embedded with PTFE guide rail soft belt. In the case of full lubrication, it can significantly reduce the friction, reduce vibration, avoid the creeping phenomenon generated in the process of feeding.

6. Operation:

The machine has a separate console. The console has the operation buttons of the full machine. The operators can focus on operating the machine at the button station.

7. Hydraulic pressure and lubricating:

The machine hydraulic pressure system is divided into two pressure degrees. High pressure is used for workbench floating. The overflow of oil of low pressure is for gearbox lubrication, helical gear lubrication and so on.

Specifications:

Name | Unit | CK5112 | Name | Unit | CK5112 |

Max. turning diameter | mm | 1250 | fast moving speed of knife rest(X axis Z axis) | mm/min | 2000 |

Max. height of workpiece | mm | 1000 | Level travel of vertical slide | mm | -20~700 |

Max. height of workpiece | t | 4 | Feeding series of knife rest(X axis Z axis) | step | no step |

Workbench diameter | mm | 1000 | Feeding range of knife rest(X axis Z axis) | mm/min | 0.1~2000 |

Workbench speed series | step | 16 step/two gears no step | Section height of knife carrier | mm | 32x32 |

Workbench speed range | r/min | 3.2~250 | Feeding alternating servomotor torque | N·m | 11 |

Max. workbench torque | KN.m | 8 | Beam travel | mm | 700 |

Main motor power | KW | 22 | Beam movement speed | mm/min | 440 |

Max. cutting force of knife rest | KN | 12 | Beam lifting motor power | KW | 2.2 |

RAM travel of vertical slide | mm | 650 | Positional precision | 0.03/1000mm |

The height of the vertical lathe can be manufactured according to the user's requirements. The specific parameters refer to the contracts and technological agreements when ordering.

Accessories and tools:

Accessory case, chuck jaw, square sleeve wrench, T-type groove boult, foundation cushion iron, foundation bolt, hexnut, washer, spring washer, hexagonal sleeve.

Packing and transportation:

Supplier provides free rain-proof and shock-proof packaging for the products.

Supplier provides free rain-proof and shock-proof packaging for the products.

After-sale service:

1.We are responsible for Installation and debugging of the products.

2.If there is something wrong with the lathe, the after-sale service personnel will reach the buyer within the specified time to determine fault, and remove it.

Main export markets:

Albania, Saudi Arabia, Indonesia, Iran, Brazil, Ukraine, Paraguay, Egypt

Certificates:

ISO9001 & CE