Single Row Angular Contact Ball Bearing

0.1~1000.0 USD

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 200,000 Piece/Pieces / Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Roll Bearings, Rod-end, Pillow Block, Needle Roller Bearing, Full Ceramic Ball Bearings |

Product Detail

| Model No.: | 7000, 5000, 3000 series |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Bmt |

| Structure: | Angular Contact |

| Type: | Ball |

| Bore Size: | 10 - 200 mm |

| Outside Diameter: | 26 - 420 mm |

| Precision Rating: | P0 , P5 , P6 |

| Number of Row: | Single Row |

| Material: | Carbon steel, Chrome steel, Stainless steel |

| Production Capacity: | 200,000 Piece/Pieces / Month |

| Packing: | According to customers' requirement |

| Delivery Date: | Upon the quantity |

Product Description

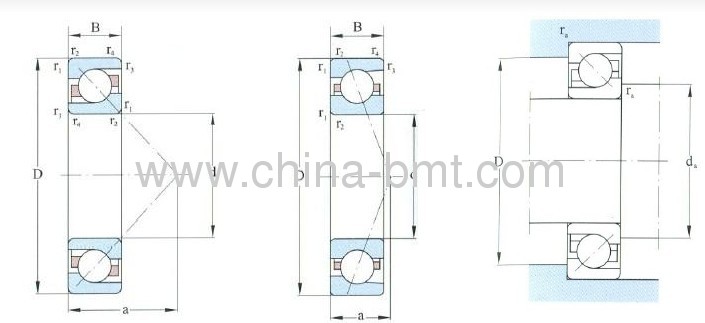

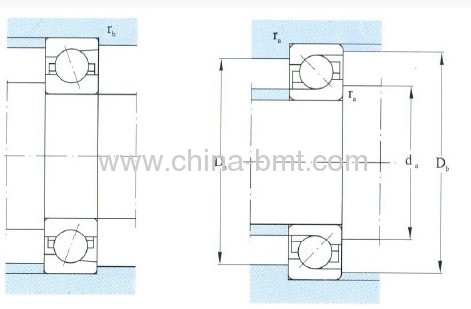

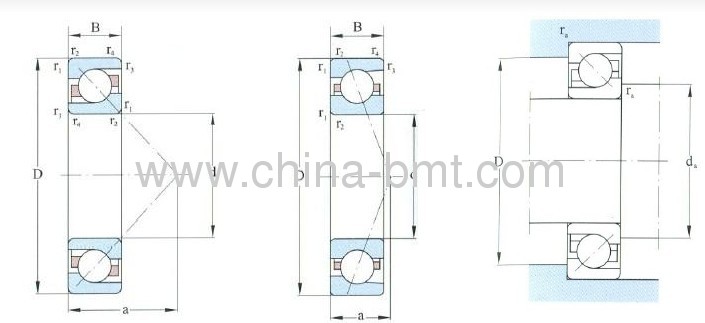

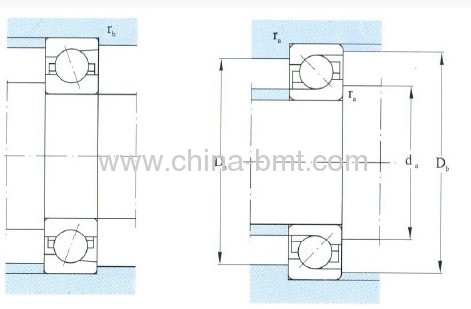

Angular contact Ball Braring

An angular contact ball bearing uses axially asymmetric races. An axial load passes in a straight line through the bearing, whereas a radial load takes an oblique path that tends to want to separate the races axially. So the angle of contact on the inner race is the same as that on the outer race. Angular contact bearings better support "combined loads" (loading in both the radial and axial directions) and the contact angle of the bearing should be matched to the relative proportions of each. The larger the contact angle (typically in the range 10 to 45 degrees), the higher the axial load supported, but the lower the radial load. In high speed applications, such as turbines, jet engines, and dentistry equipment, the centrifugal forces generated by the balls changes the contact angle at the inner and outer race. Ceramics such as silicon nitride are now regularly used in such applications due to their low density (40% of steel). These materials significantly reduce centrifugal force and function well in high temperature environments. They also tend to wear in a similar way to bearing steel—rather than cracking or shattering like glass or porcelain.

Most bicycles use angular-contact bearings in the headsets because the forces on these bearings are in both the radial and axial direction.

Our Factory

Ningbo Demy (D&M) Bearings Co., Ltd. is a leading manufacturer of ball & roller bearings and exporter of belts, chains and auto parts in China. We specialize in research and development of various kinds of high precision, non-noise, long-life bearings, high quality chains, belts, auto parts and other machinery & transmission products.

.gif)