STRANDED LOOSE TUBE ARMORED CABLE

| Min. Order: | 1 Kilometer |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 100km |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | GYD |

| Production Capacity: | 100km |

| Packing: | ROLLER |

Product Description

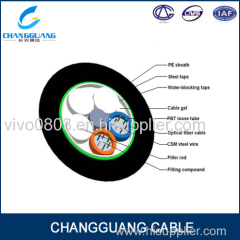

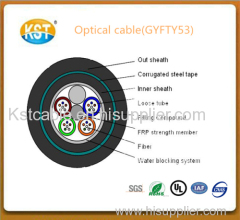

2.high strength loose tube that is hydrolysis resistant

3.special tube filling compound ensure a critical protection of fiber

4.specially designed compact structure is good at preventing loose tubes from shrinking

5.PE sheath protects cable from ultraviolet radiation

6.the following measures are taken to ensure the cable watertight.

7.steel wire used as the central strength member

8.loose tube is filling compound

9.100% cable core filling

10.APL moisture barrier

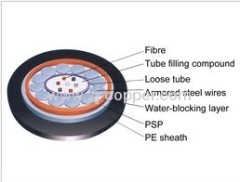

the fiber 250μm,are positioned in a loose tube made of a high modulus plasic.the tubes are filled with a water-resistant filling compound.the tube is wrapped with a layer of PSP long itudinally.between the PSP and the loose tube water-blocking material is applies to keep the cable compact and watertight.two parallel steel wires are placed at the two sides of the steel tape.the cable is completed with a polyethylene(PE) sheath.

.jpg)