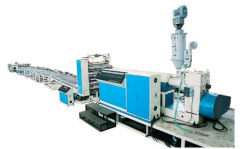

High output PVC wood plastic machine

| Payment Terms: | L/C, T/T |

|---|---|

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Service |

Product Detail

| Packing: | wooden cases |

|---|

Product Description

Wood plastic machine

1.Save electricity/space

2.High yield, stable pressure

3.Advanced design

4.ISO:9001

1.Save electricity/space

2.High yield, stable pressure

3.Advanced design

4.ISO:9001

wood plastic machine

Qingdao Mingchang General Equipment Co. Ltd is a specialized manufacture of plastic machinery and equipment. The company is located in the beautiful and rich Jiaozhou Bay with strategic location and convenient transportation. The annual output is 2000 sets.

The plastic machinerys enjoy the merits of high-tech, high degree of automation and high energy efficiency. Our products are exported to more than 20 provinces and autonomous regions for the good quality and reputation. Also, the products obtain unanimous approval from the overseas markets, such as the United, Russia, India, Pakistan, South Africa and other countries.

PVC, PE, PP wood-plastics profiles production line

Equipment features:

Wood and plastic extrusion lines: the special design of screw extruder barrel, mold machining process and production of wood and plastic products. Extruder single two-stage mixing extruding, also can directly after making two-step extrusion, save electricity, save space, has high yield, stable pressure, preheat the charger on top, first drew most main wood powder residual moisture, make host feeding section richer, Plasticizing mixing effect is good. Optimization design of screw shear small, easy use woodiness fiber cut, can make the material in the retention period inside machine. Screw machine adopt dual metal tube, wear-resisting corrosion, service life greatly extended.

This production line can produce PVC, PE or PP, wood and plastic profile tray, mainly used for packing, floor board, outdoor decoration materials, widely used. Wood powder and plant fiber additive quantity high (maximum 50-75); Equipment adaptiveness, while processing PP, PE, ABS, PS, etc.

Technical parameters

Project | YF180 | YF240 | YF300 | YF600 | YF900 | YF1200 |

Maximum plate width (mm) | 180 | 240 | 300 | 600 | 900 | 1200 |

Traction height (mm) | 150 | 150 | 150 | 150 | 150 | 150 |

Traction(kn) | 2 | 2 | 2 | 30 | 40 | 50 |

Speed (m/s) | 0-5 | 0-5 | 0-5 | 0-3 | 0-2.5 | 0-2.5 |

Auxiliary total power (kw) | 35 | 35 | 30 | 30 | 40 | 45 |

Cooling capacity (m3 / h) | 6 | 6 | 6 | 9 | 12 | 15 |

Compressed air pressure (Mpa) | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

,