Plastic Drainage Board Production Machine

| Payment Terms: | L/C, T/T |

|---|---|

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Service |

Product Detail

| Brand Name: | AORUI |

|---|---|

| Packing: | according to the custom's requipment |

Product Description

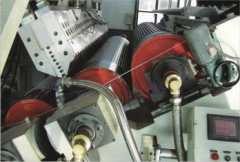

Production Process Principle Discription

1. First mix the raw materials such as PE etc. uniformly, and then put them into the extruder hopper, after being melt and plastified by the extruder, through the die be extruded out.

2. It is cooling molded by vacuum, then through air dry device, online cladding the non-woven fabrics. Through thermo melted adhesive and draw-off can reach to the I-shaped products.

3. This machine can auto winding too, when products reach to some fixed length, the cutting device can finish cut and winding to package, that can reach to finish products.

Machine Unit Production Capacity and Energy Cost

The production capacity of the machine unit is about 1.2 ton/day, installation capacity is about 50kw. Because the extruder and machine electric heater intermittent working, so the real cost power in production is about 50% of the total installation capacity.

The production capacity of the machine unit is about 1.2 ton/day, installation capacity is about 50kw. Because the extruder and machine electric heater intermittent working, so the real cost power in production is about 50% of the total installation capacity.