Imitation crab sticks production line

| Trade Term: | FOB |

|---|---|

| Payment Terms: | T/T |

| Place of Origin: | Fujian |

Company Profile

| Location: | Xiamen, Fujian, China (Mainland) |

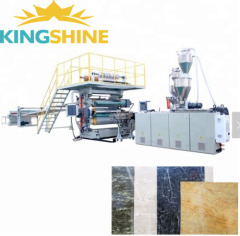

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

| Main Products: | Meat Separating Machine, Meat Collecting Barrel, Fish Paste Rotary Screen, Fish Separating Machine, Filter |

Product Description

The Manufacturing Process

1. Sorting, cleaning, and filleting

The manufacture of imitation crab meat begins by preparing the fish that will be converted to surimi. When the fish are caught in large nets, they must be manually sorted by species and cleaned. They are further mechanically sorted by size to optimize the yield of fillets. Scales are mostly removed from the fish after sorting. The fish are then conveyored to a filleting machine, which removes the head, tail, and viscera. Water washing is done next to remove excess fluids. This whole process can be done either on the fishing boat or in land-based manufacturing plants.

2. Preparing Surimi

The prepared fish fillets can then be minced, or mechanically deboned, and made into surimi. This is done using a mechanical deboner, which removes the skin, scales, fins, and bones. This machine is made up of a thick rubber belt and a perforated drum. As the fish passes through this machine, the belt presses it against the drum, forcing the soft flesh particles to the interior of the drum while leaving the harder scales and bones on the outside. The drum is constantly rotated and the excess outer material is scraped off and collected in a waste bin.

3. The minced fish is next thoroughly washed with water in a process called leaching. This is done in a large tank which is emptied and refilled with water repeatedly. Leaching removes many undesirable water soluble materials such as fats, inorganic salts, and some proteins. After the final leaching cycle, the mince is partially dewatered before moving to the refining phase of manufacture.

4. Refining machines are made up of a cylindrical screen and a rotor. The mince is selectively separated with the soft, white meat in the front of the machine and the harder, browner meat in the back. This refining step removes any residual materials such as skin, bones, and scales. The refined mince is sent to a screw press that removes all excess water.

5. After dewatering, cryoprotective compounds such as sugar and sorbitol are added to the mince to help protect the fish proteins from breaking down during the final, freezing stage of manufacture. The final step in surimi production involves packing it in polyethylene bags in 22-lb (10-kg) blocks and quickly freezing it to below -4°F (-20°C). The surimi is stored at this temperature until it is ready to be used.

6. Forming the crab meat

The frozen surimi is converted to imitation crab meat through various steps. First, it is warmed to about 25°F (-4°C), then sliced into coarse flakes. In a process known as comminution, the surimi flakes are then mixed together in a stone bowl grinder with other ingredients in the crab meat recipe. These ingredients include starch, salt, natural crab meat, egg white, and flavors. This mixture results in a thick surimi paste, which is then transferred to a holding tank.

7. The paste is pumped from the holding tank to the sheet-forming equipment. Here, continuous sheets of surimi, about 10 in (25 cm) wide and 0.05 in (1.2 mm) thick are produced. Due to the chemical nature of the surimi protein, these sheets are very smooth. After the sheets are formed, they are sent to machines for the initial cooking. This cooking helps set the sheets and prepares them for the slitting operation, which gives the meat the appearance and texture of crab meat.

8. The slitting is done by a machine which is composed of two steel rollers that cut the surimi sheet into thin 0.1 in (1.5 mm) wide strands. These thin strands are then bundled and rolled into a rope. This rope is given the appropriate color, wrapped, and cut to the desired size. It is then steamed cooked, forming a product that looks and tastes very much like the crab meat it is designed to imitate.

9. Packaging

Imitation crab meat is mechanically vacuum packed in thermoformed trays. This protects the meat from contamination and provides an appealing look. Some common plastics used for packing include polyethylene, nylon, and polyester. After packing, the imitation crab meat is typically pasteurized in a steam cooker. This step helps prevent bacterial growth and increases shelf life.