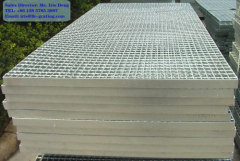

steel grating

100.0~10000.0 USD

| Min. Order: | 100 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | JH-033W |

|---|---|

| Means of Transport: | Ocean |

Product Description

Steel Grating is made bystainless or mild steel of certain sizes through the processing ofgrooving, lock-pressure, welding, finishing and other treatment.Industrial bar gratings can be actually made from copper, aluminum andother materials, while galvanized steel grating is the mostly used one due to its economic cost and good property.

Steel grating,with robust design and spanning abilities, is very strong and safe forthe support of floors and elevated walkway. It can be used for ceiling,interior decoration, decoration, platform aisle, ventilation windows,(Wells), advertising plaque and other construction.

Steel Grating Materials:

Mildcarbon steel provides an economical, high strength for uses in mostindustrial and commercial applications. Gratings of OtherMaterials:Stainless Steel Grating

Aluminum Grating

Fiberglass Grating

The advantages, specific application and features of steel grating:

Steel grating offers the following advantages compared with steel grid sheets:

Steelgrating has light weight, good strength, large carrying capacity andcan save materials and cost. It offers good ventilation of light andwind, a modern sense, aesthetic appearance and anti-skid safety. It isalso easy to clean, easy to installation and durable for uses.

Stainless steel bar gratingis a choice for corrosive environments such as chemical, food and hydroprocessing areas. It is available in welded and press locked as well asin many bearing bar sizes.

Steel grating,with robust design and spanning abilities, is very strong and safe forthe support of floors and elevated walkway. It can be used for ceiling,interior decoration, decoration, platform aisle, ventilation windows,(Wells), advertising plaque and other construction.

Steel Grating Materials:

Mildcarbon steel provides an economical, high strength for uses in mostindustrial and commercial applications. Gratings of OtherMaterials:Stainless Steel Grating

Aluminum Grating

Fiberglass Grating

The advantages, specific application and features of steel grating:

Steel grating offers the following advantages compared with steel grid sheets:

Steelgrating has light weight, good strength, large carrying capacity andcan save materials and cost. It offers good ventilation of light andwind, a modern sense, aesthetic appearance and anti-skid safety. It isalso easy to clean, easy to installation and durable for uses.

Stainless steel bar gratingis a choice for corrosive environments such as chemical, food and hydroprocessing areas. It is available in welded and press locked as well asin many bearing bar sizes.

Steel Grating Materials: The most common material isType 304 (SUS304), however, Type 316 (SUS316) or Type 316L (SUS316L) isalso available. 304 stainless steel is the most popular type containsboth chromium and nickel to provide excellent balance resistance andworkability.

.jpg)