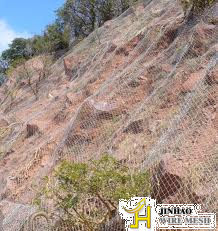

Rockfall Netting

3.0~22.0 USD

| Min. Order: | 1000 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 500000 Square Meter/Month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | JH--037A |

|---|---|

| Means of Transport: | Ocean |

| Application: | Others |

| Type: | Woven |

| Material: | Others |

| Brand Name: | JINHAO WIRE MESH |

| Mesh Size: | 2m wide and 25m in Length |

| . Preparation of the surface tobe blanketed (removal of loose rock particles, barring down ): | Placing the netting over the surface to be protected by lifting the rolls to the top of the face and then unrolling the |

| Fixing the netting to the wall and tying them: | Final fastening of the net at the top, foot and if necessary the face. |

| Production Capacity: | 500000 Square Meter/Month |

| Packing: | as Customers Require |

| Delivery Date: | 3--40days |

Product Description

Rockfall netting a hexagonal woven wire mesh, supplied in rolls 2m wide and 25m in. Length. Preparation and Placement

Rockfall Netting Placing double twist mesh rolls is an operation generally performed on faces or slopes close to the vertical and sometimes of considerable height. Although placing of the mesh may vary from site to site, the work may be reduced to four main phases.

1. Preparation of the surface tobe blanketed (removal of loose rock particles, barring down).

2. Placing the netting over the surface to be protected by lifting the rolls to the top of the face and then unrolling them.

3. Fixing the netting to the wall and tying them.

4. Final fastening of the net at the top, foot and if necessary the face.

2. Placing the netting over the surface to be protected by lifting the rolls to the top of the face and then unrolling them.

3. Fixing the netting to the wall and tying them.

4. Final fastening of the net at the top, foot and if necessary the face.

Rockfall Netting is wire mesh netting which is used to prevent rocks from falling onto the road, railways and other structures. The Rockfall Netting is made of galvanized or PVC coated double twisted steel woven wire in acc. With STM A641and EN10223-3. Due to the unravelling character of double twist, the Rockfall Netting can withstand huge forces and will not unravel even if a wire is broken. Rockfall protection netting with a PVC coating can be used in aggressive environments. In addition to galvanization, the steel wire is coated with a PVC layer of a nominal thickness of 0.50 mm. The technical characteristics and the resistance of the PVC to aging meet the relevant standards

.jpg)

.jpg)