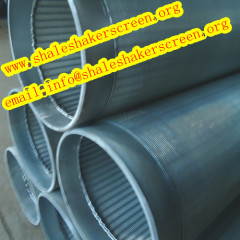

wire wrapped screen

45.0~225.0 USD

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, MoneyGram |

| Supply Ability: | 15,000 pieces per month uaually |

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association |

| Main Products: | Stainless Steel Wire Mesh, Johnson Screen Filter, Johnson Screen Pipe |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Structure: | Cartridge Filter |

| Function: | Water Filter |

| Material: | Others |

| Brand Name: | hengying |

| slot size: | 0.25mm-1.0mm |

| rod shape: | V-shape,round shape or trapezoid shape |

| Production Capacity: | 15,000 pieces per month uaually |

| Packing: | as the clients' requests completely |

| Delivery Date: | in 10 days usually ,it's up to the order mainly |

Product Description

Water well screen /wedge wire screen/screen pipe/wire wrapped screen pipe

wire wrapped screen

Made in :Hebei Hengying Wire Cloth Co.,Ltd ,HeBei Province ,China.

wire wrapped screen

Made in :Hebei Hengying Wire Cloth Co.,Ltd ,HeBei Province ,China.

Materials: carbon steel and stainless steel (302,304,304L,316,316L etc).

characteristics:The welded stainless steel water well screen is made up of rods and warps. The rod can be round wire, triangular wire or trapezoid wire. The warp is triangular wire (V-shaped wire). Water well screens have a structure and high open area as well as accurate slot dimension. At the same time, water well screens are heat-resisting, anti-corrosive and they have many good characteristics ,such as good machine capability, last long, safety and reliability and so on . It can be used in many kinds of medium filterings.

Uses: The strainer is a kind of filtered water tubing with the perforation .It can be used in the deep well pump , diving the water pump , the water-treating equipment, the environmen protection, the sea water transformation into the industrial water , water desalination treatment for life, running water treatment, water softening treatment, the petroleum industry such as the petroleum product terminal filters , the chemical acid, the alkali liquid filters, the ethyl alcohol or the organic solution recycling filters and so on .

Advantage

- A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone.

- A "V"shaped profile wire which avoids clogging and ensures an uninterrupted flow.

- A uniform and efficient well development due to the continuous slot opening.

- Ladder-like wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

- 5.Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

Features of products

1. Screens with high open area are more suitable for the construction of high-quality water wells, oil wells and gas wells.

2. Low cost operation

Screens with high open area shall favor groundwater infiltration. Abundant water shall reduce the water level's down, thus to save energy consumption.

3. Reduce the abrasion of the pump

Under the same condition, high open area can make the speed of groundwater's entering into the screen much slower than any other filtration apparatus, which will avoid sand's entering into screen because of high pressure, thus reduce the abrasion of the pump.

4. Extend the life span of wells

Comparatively, groundwater's entering into screen with higher open area is much easier than the entering into lower open area screen. The slow water flow shall extend the life span of wells.

2. Low cost operation

Screens with high open area shall favor groundwater infiltration. Abundant water shall reduce the water level's down, thus to save energy consumption.

3. Reduce the abrasion of the pump

Under the same condition, high open area can make the speed of groundwater's entering into the screen much slower than any other filtration apparatus, which will avoid sand's entering into screen because of high pressure, thus reduce the abrasion of the pump.

4. Extend the life span of wells

Comparatively, groundwater's entering into screen with higher open area is much easier than the entering into lower open area screen. The slow water flow shall extend the life span of wells.

Styles of connection: by welding or by threaded male/female coupling.

we can produce length up to 6.5m.

Most of all ,we can design the product as the client's request.

.jpg)