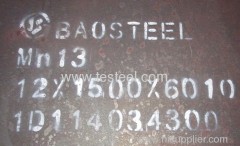

abrasion resistant steel plate X120MN12 1.3401

2300.0~2450.0 USD

| Min. Order: | 5 Ton |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000t/m |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Trading Company |

| Main Products: | High Manganese Steel Plate 1.3401China Mn13, High Manganese Steel Plate 1.3401, Alloy Steel Sheet China Mn13, Abrasion Resistant Steel Sheet, ALLOY STEEL PLATE |

Product Detail

| Model No.: | 1.3401 MN13 |

|---|---|

| Means of Transport: | Ocean |

| high manganese steel plate X120MN12: | alloy steel plate x120mn12 |

| Production Capacity: | 10000t/m |

| Packing: | normal packing |

| Delivery Date: | within 45-50 days |

Product Description

Grade:120Mn12 < W1.3401 - AISI A 128 (A) - GOST 110 F 13 L - JIS SCMnH 1/11>

Germany standard G-X120Mn12

American standard US A128

Europe standard X120Mn12

China Mn13

ZGMn13 China cast steel

high manganese steel

hot rolled plate hot round bar

Chemical composition (%)

C | Si | Mn | P | S | Cr |

1.1~1.3 | 0.3~0.5 | 12.0~13.0 | ≤0.100 | ≥0.040 | (1.50) |

mechanical properties

tensile strength Rm(Mqa) | yield strength Re(Mpa) | reduction of area A(%) | ballistic work Akv(J) |

880~1130 | ≥410 | ≥40 | 124(normal temperature) |

Specification scope commer specification 6-30mm. Special specification 1-5mm.

Shipment data one and half month without any special situation.

Mn13 we have the stocks Mn13 6,7,8,10,12,13,15,20,25,30 unit/mm.

Mn13(X120Mn12)is the best choice for resist-high impact ,the material of big stress in wear-resistance.The high manganese steel have two biggest features: one is external impact more bigger ,the wear-resistance of appearance is more higher ; another is with the gradually abrasion of densified laminated appearance, new densified laminated process is formed continually.

Mn13(X120Mn12)wrought-steel plate have wonderful abrasion resistance of high impact abrasion and big stress abrasion, when using it will not appear crash.It also has the excellence of easy for cutting ,welding ,curving and other mechanical properties for process.The traditional used high chrome forging only have the good wear-resistance of moving abrasion. Mn13(X120Mn12)rolled plate is reduced the cost of useing for quick-wear part of low equipment and save the overhaul fee of equipment,so it improves the competition.