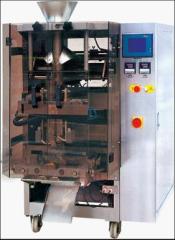

SP-2000KB Back seal powder/granule packing machine sachet pouch vertical form-fill-seal machine

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 pcs/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Wenzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Ro Water Plant, Shrink Packaging Machine, Shrinkwrap Machine, Sleeve Wrapper, Shrinkwrap Packaging Machine |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Processing: | Filling Machine |

| Automatic Grade: | Automatic |

| Type: | General |

| Usage: | Others |

| Packaging: | Plastic |

| Production Capacity: | 20 pcs/month |

| Packing: | wooden crate |

| Delivery Date: | 10-20 days |

Product Description

PLC Controlled main packing machine, equipped with auto volumetric cup dosing system,

material lifter/conveyor and the finished product conveyor. It has an extensive range of package,

suitable for packing of each kind of item such as grains, refined sugar, blocks, bars and powder, etc.

Standard Features:

It integrates metering, bag-making, packaging, sealing, printing and counting.

Standard positioning with servo film transporting system; stable for transporting film with two synchronous belts;

High automation with auto correction function.

Reasonable structure, convenient adjusting operation and maintenance.

Specification:

Packing speed: 5-50 bags/min

Bag size: Length: 50-300mm; Width: 60-200mm

The maximum width of packing film: 440 mm(diameter)

Thickness of film: 0.04-0.08mm

Bag making mode: Pillow-type bag, standing bag.

Range of measuring: 150-1000 gm(max)

Air consumption: 200L/min; 0.7Mpa

Power/voltage: 2.2 KW/220V, 50 Hz

Dimension (LxWXH):1400×970×1600mm

Weight: 400kg

Weight: 400kg

Body: Steel with painting, S/S304 for the parts contact the packed material.

Country of origin of mainequipments:

Country of origin of mainequipments:

PLC: Mitsubishi (Japan)

Touch Screen: Delta (Taiwan)

Servo motor: Panasonic (Japan).

Photo Sensor: Optex (Japan).

Pneumatic component: AIRTEC (Taiwan).