Used Buhler Rice Polisher Rice Polisher DRPN-F

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | T/T |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Other |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | Buhler |

| Brand: | Buhler |

| Model: | DRPN-F |

| Product Name: | Rice Polisher |

| Condition: | Used |

| Manufacture Year: | 2011 |

| Location: | China Mainland |

| Lead Time: | Depend on Order |

Product Description

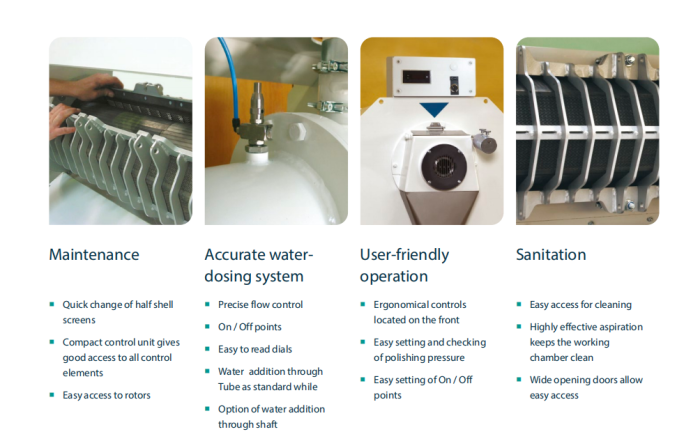

HighPolyTM For excellent rice surface and brightness.

Application

The HighPolyTM polisher is used in the final stage of processing to produce rice with a smooth, dust free surface which flows freely like water through the fingers. Clear transparent packs which show the contents are an ideal way to pack the HighPolyTM processed rice which, with its high gloss and pearly lustre makes it a highly visible and attractive product on market shelves. If required, the machine can also be used for standard dry polishing.

Excellent rice surface and brightness

High head rice yield

Low power consumption

Long life of wear parts

Easy to operate

Function

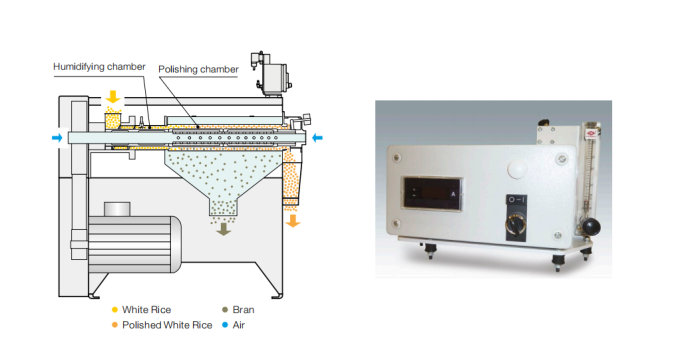

The product falls into the inlet and is conveyed through the feed screw into the sieve basket. A uniform water film is applied to the product via the mixing tube using a nozzle. The product is gently rubbed against itself in the sieve basket by a rotating cam shaft, through which the surface is made shiny by polishing. The fully polished product leaves the machine through the outlet. The aspiration system produces an air current, which is routed through the work area through the hollow shaft, which is open on both sides (from inside to outside). This cools the rice and the rice polishings are separated (by a sieve). Additional air enters through the adjustable slots in the doors.

Water metering unit

A well-controlled flow rate of water and a uniform process are critical in order to achieve an excellent polish on the rice. The amount of water required is controlled by the water metering unit. Via a current transformer, the ammeter receives the present current consumption of the motor. The ammeter has 2 electronic switch points with which the operator can set the automatic start/stop of the water. The operator can adjust the water volume via the needle valve on the flow meter. Ammeter with digital display indicator Water addition up to 100 l/h