Used Buhler BSPB Rice Polisher Manufacture Year 2011

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | T/T |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Other |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Brand Name: | Buhler |

| Brand: | Buhler |

| Model: | BSPB |

| Product Name: | Rice Polisher |

| Condition: | Used |

| Manufacture Year: | 2011 |

| Location: | China Mainland |

| Lead Time: | Depend on Order |

Product Description

TopWhite. Quality. Performance. Economy

The Bühler TopWhiteTM whitener BSPB is used for whitening (i.e. removal of bran) of brown rice to white rice. It uses the vertical abrasive top to bottom working principle, which has been proven to achieve the highest whole grain yield. Its main fields of application are the rice milling industries. The whitener can also be applied to grain, wheat, barley, and peas processing industries.

Flexible Adaptation

Uniform and gentle whitening

Intensive cooling

High capacity and efficiency

Minimum space requirement

High product quality

High level of sanitation

Low power consumption

Easy Maintenanc Highly flexible and adaptable rice production.

Highly flexible and adaptable rice production.

The TopWhite™ whitener BSPB adapts easily to all varieties of rice for whitening. The various options make the machine most suitable for all sorts of rice and ensure the production of perfect white rice of all kinds.

High efficiency thanks to gentle whitening process.

Through a smooth flow of rice and the efficient aspiration system inside the machine, the rice is whitened very gently. This minimizes breakage of the rice during the whitening process and ensures maximum profit.

Guaranteed uniformity and quality of the end product.

The option of various adjustments even when the machine is in operation – like counter weights or the adjustable gap between screens and stones – enables uniformity and guarantees high quality of the end product. Working principle

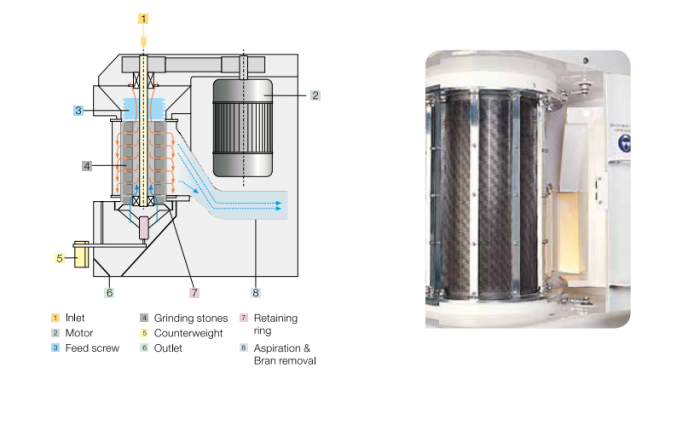

Working principle

The TopWhiteTM uses the vertical abrasive, top to bottom working principle which has been proven to achieve the highest whole grain yield. The grain enters the whitener via two inlets and is guided into the processing chamber by a feed screw. There, it is exposed to careful whitening of the grain surface between the six abrasive rings and the screen. As the rotor is dynamically balanced a smooth running is assured. The whitening intensity is controlled by two easily adjustable means the counterweight of the retaining gate and the gap between rotor and brakes. For coarse adjustment, the vertical brakes attached to the sieve basket are moved simultaneously by simply turning a handwheel and thereby tuning the resistance inside the chamber. The fine setting is done by changing the counterweight position of the retaining gate, thus controlling the pressure. The gravity flow of the product allows a trouble-free restart in case of an emergency shut-down.

Aspiration system

The TopWhiteTM is equipped with an optimised aspiration system that fulfills two tasks very efficiently: it cools the rice and thereby reduces breakage and supports the conveying of the bran out of the whitening chamber into the exhaust system. Therefore, aspiration air is guided partly through the product and partly around the screens. The aspiration hood, being easy to open or remove, gives full access to the heart of the machine. For best sanitation, no moving parts are involved in the bran removal system. The ammeter and the vacuum gauge allow the monitoring of the motor current and the negative pressure of the applied exhaust system.