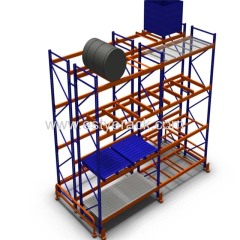

Customized Heavy Duty Storage Selective Pallet Racking

| Min. Order: | 100 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 5000sets/month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Weifang, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

Product Detail

| Model No.: | ESTYE-S005 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Scale: | Heavy Duty |

| Type: | Pallet Rack |

| Brand Name: | ESTYE |

| Capacity: | 1-3T/Layer |

| surface treatment: | powder coating spray glavanized |

| Certificate: | ISO 9001:2000 |

| material: | cold rolled steel sheet |

| color: | RAL color code |

| height: | 10000m |

| length: | 2300mm or 2700mm |

| max load: | 1500kg to 3000kg per layer |

| Production Capacity: | 5000sets/month |

| Packing: | Exporting packing. |

| Delivery Date: | Within 15 working days |

Product Description

"Customized Heavy Duty Storage Selective Pallet Racking" refers to a type of storage system commonly used in warehouses and distribution centers to store and organize palletized goods. It is designed to maximize storage space and provide easy access to individual pallets.

Here are some key features of customized heavy-duty selective pallet racking:

1. Customization: The racking system can be customized to meet specific storage requirements, such as height, width, and depth, to accommodate different pallet sizes and load capacities.

2. Heavy-duty construction: The racking system is built with high-quality steel components to provide strength and durability for storing heavy loads.

3. Selective accessibility: Each pallet can be accessed individually, allowing for easy picking and replenishment of goods. This makes it suitable for fast-moving inventory and high selectivity requirements.

4. Adjustable beam levels: The racking system typically consists of vertical upright frames and horizontal beams. The beam levels can be adjusted to accommodate different pallet heights and optimize storage space.

5. Safety features: The racking system includes safety measures such as beam connectors, row spacers, and column protectors to ensure stability and protect against accidental damage.

6. Versatility: The selective pallet racking system can be integrated with other storage solutions, such as mezzanine floors, carton flow racks, or wire mesh decking, to create a comprehensive storage solution tailored to specific needs.

It's important to note that the design and implementation of a customized heavy-duty selective pallet racking system should be done by professionals experienced in warehouse planning and storage solutions. They can assess your specific requirements and provide the most efficient and safe storage solution for your business.

| Upright size | Height (mm) | Max load for the upright frame (kg) | Beam szie |

| 55*60*1.2 | 2 | 2 | 40*60*1.5 |

| 55*60*1.5 | 4 | 4 | 40*60*1.5 |

| 55*60*2.0 | 4 | 5 | 40*60*1.5 |

| 60*70*1.8 | 6 | 5 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 60*70*2.0 | 6 | 7 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 60*80*1.8 | 6 | 6 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 60*80*2.0 | 6 | 8 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*90*1.8 | 10 | 8 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*90*2.0 | 11.5 | 10 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*100*1.8 | 11.5 | 10 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*100*2.0 | 11.5 | 12 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 |

Selective pallet racking systems feature:

1.Pallet racking is specilized storage rack for pallet.It is made of the upright frames and beams.It can be prevent the imbalance for the loose of the screws.

2.on the upright ,there are two straight line of tear drop hole with 50mm between two holes.So the beam can be adjusted every 50mm.

3.The box beam is composed of two eclosed C-profiles weld with one time punch shaped connector in both end.It can prevent torsion and deflection.

Name | Euro Pallet Rack | ||

Size | Customized Size | Material | Steel |

Depth/Width/Height | Customized | Color | Customized |

Weight Capacity | 500~5000kg | Certification | AS4084-2012 / CE / ISO / RMI |

Pitch holes | 50.8mm | Surface finish | Powder Coated |

Usage | Warehouse Storage System | Application | Widely Used |

Free Sample | Available (Delivery Cost on Buyer) | OEM | Available |

FAQ

1, What is the material being used for your products?

---Mild steel Q235, Q195

2, How is the goods being packed?

---Plastic banding + Stretch film wrapped, palletized for easy loading and unloading with a standard forklift truck or pallet jack.

3, What is the payment terms I can get?

---TT or L/C at sight, DP, etc.

4, What kind of finish do you provide for your goods?

---A. Electro galvanized/Zinc plated: the zinc serves as a sacrificial anode( indoor storage)

B. Hot dip galvanized: it forms a coating of corrosion-resistant zinc(indoor/outdoor and cold storage)

C.Powder coating: a type of coating that is applied as a free-flowing, dry powder(indoor/outdoor storage)

5. What is the loading capacity?

---In general, we have a light duty(100~300kg) model, medium duty(400~800kg) model and

heavy duty(1000~1700kg) model available for your choice.

6. Which product can be used in cold storage?

---Mobile rack, wire container, and roll cage are all widely used in cold storage.

7.I like your design, but couldn't find the right model from the products list, is custom size available?

---Yes, we do custom products and projects.

8 I would like to have my own design products and qty is not that big, is it ok?

---Yes, we can go with your custom design, no matter small or big qty, however, pls understand the cost will be different.

9 I don't have drawing or picture available for the custom products, could you design it for me?

Yes, we can make the best suitable design for you but do need to know the details, such as

a) dimension b) loading capacity c)stackability d)operation environment.

10 What is the minimum quantity I can order?

--1x20'GP - qty is variable depending on the size

11 What is your average production lead time?

--2-3 weeks against formal order and deposit.

12 Do I get any guarantee from your company?

-3~10 years warranty in the case that

A) Proper handling during operation, correctly forklift handling while stacking/unstacking

B) Overloading is prohibited

C) Environment request indoor, dry and not humid circumstance, do not contact with any corrosive chemical material (for zinc plated and powder coated products, no limitation for hot-dip galvanized).