heavy duty cantilever rackings

| Min. Order: | 120 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 5000 sets per month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Weifang, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

Product Detail

| Model No.: | ESTYE-G005 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | ESTYE |

| certificate: | ISO9001:2000 |

| color: | international RAL color code |

| surface treatment: | powder coating spray glavanized |

| length of the arm: | 800mm |

| height: | 3000mm |

| layer: | 3 |

| material: | Steel, Cold Rolled Steel Q235 |

| application area: | warehouse for pipes lumber carpet |

| load: | 500kg to 1000kg per arm |

| width: | 1000mm to 1500mm |

| Production Capacity: | 5000 sets per month |

| Packing: | normal packing |

| Delivery Date: | 10 working days after the 30% deposit |

Product Description

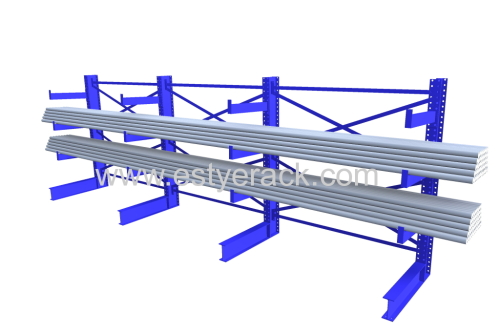

Cantilever Pallet Storage Rack is just the ticket if you need to store long, bulky items such as:

Lumber, Metal Beams, Pipes, Molding, Metal and Plastic Sheets, Tubing, Carpeting.

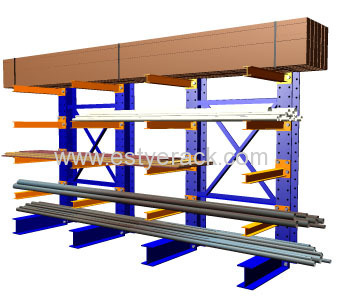

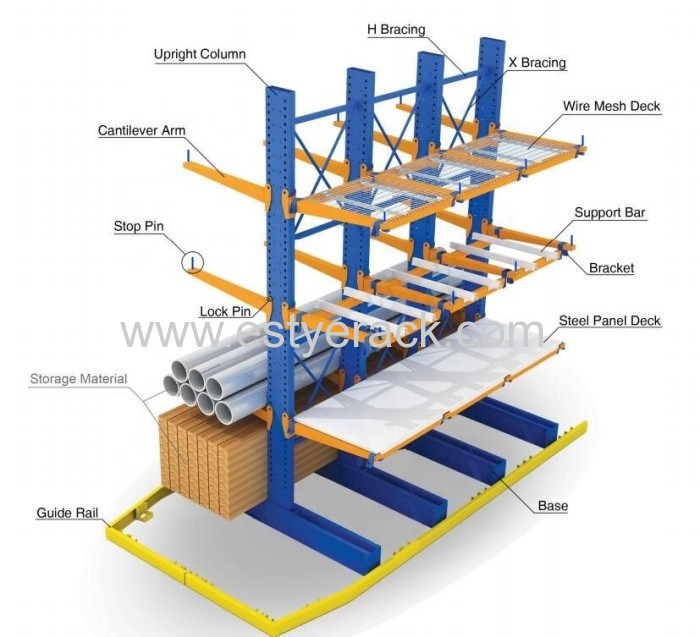

Systems consist of columns with one or two horizontal beams at the base to provide stability, with a series of arms attached that loads can be placed on. Rows can include both single- and double-sided cantilever. Single sided is usually placed against the wall allowing access from one side only. Double sided cantilever can be accessed from both sides.

Name | Cantilever Racking | Material | Q235B Steel |

Size | Customized Size | Color | Customized Color |

Depth | Customized | Weight Capacity | 1000kg/arm |

Width | Customized | Height | Customized |

Finish | Powder coating; Hot Dip Galvanized | ||

Packing | Export Package | ||

Certification | RMI/CE/ISO/TUV/AS4084-2012 | ||

MOQ | One 20ft/40ft Container | ||

Free Sample | Available (Delivery Cost on Buyer) | ||

OEM | Available | ||

Cantilever pallet rack systems are available in both roll formed and structural steel designs.

Drop-in steel decks and a spring-loaded entry guide system are available for safety and protection of both merchandise and the pallet racks system.

A wide range of load capacities are available to meet your specific weight, size and space requirements.

Cantilever pallet racks systems are available in medium and heavy-duty versions and are determined by the weight, size and height of the stored product. Their interlocking parts are easily assembled and are adaptable to meet future needs.

Heavy Duty Cantilever is ideal for loads with high-load bearing capacity that are handled and loaded by lift trucks, mobile cranes, stacker cranes, etc.

Cantilever pallet rack systems are available in both roll formed and structural steel designs.

Cantilever racks can be used indoors or outdoors. With the addition of decking, cantilever racks can also provide storage similar to pallet racking, with the advantage that, with no front column, there is easy access for loading and unloading as each storage slot is immediately accessible. This can lower your handling time and costs. The arms provide for adjustable rack openings that easily accommodate various load dimensions.

Cantilever pallet racks systems are available in medium and heavy-duty versions and are determined by the weight, size and height of the stored product.

Cantilever racking allows you to stack long loads, such as timber, trusses, pipes or plywood. The key comes to down to proper design before installation. While adjusting the height and arms of the racking is easy, moving the beams and bases are a bit more challenging. Be sure to include wide operating aisles for forklifts, pallet jacks and other material handling equipment.

Cantilever racking can be assembled in many different formations, most commonly up against a wall for single-sided racking, or they can be placed back to back for double-sided racking. The space between the uprights can be adjusted to fit into corner, crook or cranny in your warehouse to make the most of all available space.

Cantilever racking provides your organization with the means and methods to increase productivity, safety and the work environment as you look to grow and build your business.

FAQ

1, What is the material being used for your products?

---Mild steel Q235, Q195

2, How is the goods being packed?

---Plastic banding + Stretch film wrapped, palletized for easy loading and unloading with standard

forklift truck or pallet jack.

3, What is the payment terms I can get?

---TT or L/C at sight, DP etc

4, What kind of finish do you provide for your goods?

---A.Electro galvanized/Zinc plated: the zinc serves as a sacrificial anode( indoor storage)

B.Hot dip galanized: it forms a coating of corrosion resistant zinc

(indoor/outdoor and cold storage)

C.Powder coating: a type of coating that is applied as a free flowing, dry powder

(indoor/outdo