heavy duty steel pallet rackings

| Min. Order: | 150 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 5000sets per month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Weifang, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

Product Detail

| Model No.: | ESTYE-S008 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | ESTYE |

| certificate: | RoHS/CE/ISO9001:2000 |

| color: | international RAL color code |

| surface treatment: | powder coating spray glavanized |

| style: | heavy duty |

| upright: | 60*80/70*90/70*100mm |

| beams: | 80*50/100*50/120*50/140*50mm |

| material: | Q235 Steel |

| layer: | 4 or as require |

| application area: | industrial warehouse |

| Production Capacity: | 5000sets per month |

| Packing: | standard export package |

| Delivery Date: | 20 days after the 30% deposit |

Product Description

Heavy duty pallet rackings, storage heavy duty pallet rackings, heavy duty storage heavy duty pallet rackings, drive-in metal industrial pallet rackings

Heavy Type Beam Racking System, and known as beam racking, or racking of position type, belonging to pallet racking category, a variety of storage rackings system in the domestic, the most common form of a racking. Frame(Upright) + beam to form of fully assembled structure, the structure simple and effective. Container storage unit according to the characteristics of installed equipment such as: every file, steel plates (with wooden shelves), metal mesh deck, storage cage rail, frame drums and other functional accessories. Unit load devices to meet the different forms of cargo storage. Heavy duty racking is the most common form of rackings, each bearing more than 500Kg, called the heavy-duty racking. They have a good efficiency, heavy items can be stored.

The Load Table:

Length | 1500 | 1800 | 2000 | 2300 | 2500 | 2700 | 3000 | 3300 |

Beam Specification | Load/kg | |||||||

80×50 | 3000 | 2300 | 1800 | 1500 | 1200 | 1000 | 800 | 700 |

100×50 | 4000 | 4000 | 3000 | 2400 | 2000 | 1750 | 1400 | 1100 |

120×50 | 4000 | 4000 | 4000 | 3500 | 3000 | 2500 | 2000 | 1800 |

140×50 | 4000 | 4000 | 4000 | 4000 | 4000 | 3800 | 3000 | 2500 |

The main features of Selective Pallet Racking:

1. Usually the goods through pallet, storage cage, and other unit load devices shelf packaged into custody after. 2000kg per unit load is generally less than two units on each floor are usually placed.

2. Is the most common and widely used one racking, suitable for most goods in the warehouse or products.

3. With 100% arbitrarily selected characteristics of the goods. Handling machinery such as forklifts and other cargo can reach any place to store operations, store operations easy and fast!

4. By mechanical handling equipment for storage operations.

5. Rack unit span is generally less than 4m, depth 1.5m or less, low, high storage racking height is generally less than 12m, ultra-high-bit storage shelf height is generally less than 30m (basically all of these storage warehouse, the total high rack by the several segments within the column constitutes 12m).

6. Be able to freely adjust the multiple of 50mm and 75mm on each storey.

Heavy (beam type) commonly used cold-rolled deformed steel shelf production, column by the90*60,90*67,90*78,120*80 Ω red diamond-shaped hole from the surface of steel, beams from the 80*50-90*50-100*50-110*50-120*50-140*50-160x50 lock pendant and welded beams with into general use pallets instead of shelves to facilitate forklift handling. Layer 1 ton to 5 ton truck design, the surface electrostatic spray, rust and corrosion water more capable, high safety factor, plug-in combination, do not need screws and welding, assembly is very easy to make full use of space area, providing storage capacity.

Selective Pallet Racking Structure:

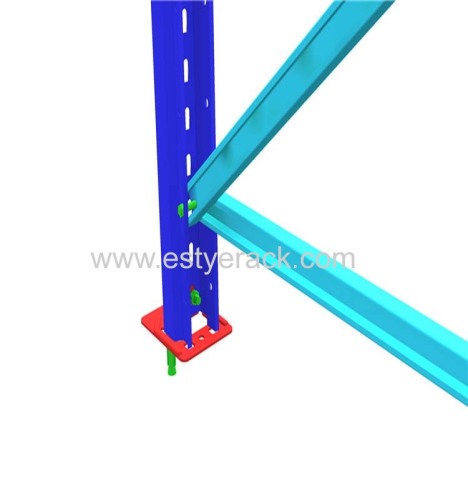

Heavy Type Beam Racking System by the columns, beams, cross bracing, diagonal bracing, and self-locking bolt assembled, can effectively prevent the bolts loose shelves after the trigger instability; beam using a special cold P-type closed beam; The structure is simple and reliable, light weight, high capacity and low cost characteristics; column card column connection with the special design with the safety pin, you can ensure that the beams would not fall off the external impact; laminates made by the international strip laminates, with load strong, resistant to wear and tear, the replacement of simple, low-cost maintenance features.

Installation: First, the horizontal pull (cross brace), stayed (braces) with the screws installed in the columns. The assembled the two frames (one frame= two column + horizontal pull + a few beams) pieces erected on the ground from the column was adjusted to the length of the beam after the beam can be installed. Installed when the Vice-frame column piece is installed first, and then packed column piece on the side away from the main frame of film from the column was adjusted to the length of the beam after the beam can be installed.

FAQ

Q: Are you manufacture or trading company?

A: We are manufacture. Our factory has been specializing in supermarket shelves, warehouse racks and different,kinds of display stands since 2001.Q: Where is your factory? Can I visit ?

A: Our factory is located in Weifang, Shandong. You are warmly welcome to visit whenever you are available.Q: What is your delivery time?

A: In general, within 15 days. It also depends on the order quantity and shelving design.Q: What is the term of payment?

A: Payment terms: 30% of deposit upon signing the PI, and balance will be cleared by T/T before delivery.Q: Are samples available?

A: Yes, samples are available at any time. We charge some sample cost and will return it during the next order.Q: How could I install the racks?

A: We provide detailed install instruction for every type of shelf. If needed,we can also ask engineers to teach you for free.Q: Could you produce according to customers' design?

A: Sure, we have very rich experience in customizing shelves.Q: Do you produce shelf with different kinds of materials?

A: Yes,our products are mainly made of metal but we also produce accessory shelves or displays with wood,titanium alloy,acrylic,glass,etc.wall recessed jewelry cabinetQ: What are main rack and add on rack?

A: The difference between these two kinds of racks is upright. Main rack is the start rack with 2 uprights and add on rack is the continue rack with only 1 upright. For example, if there are 15 wall racks against the wall, the structure will be 1 main rack+ 14 add on racks.Q: What is the manner of packing?

A: Generally, shelves are flat packed by air bubble film/ film in standard export cartons. Other packing like wooden box are available to clients' requirement.