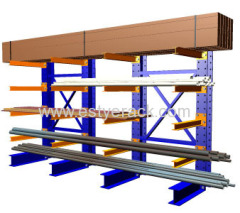

heavy duty cantilever racks for long pipes

| Min. Order: | 120 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 5000 sets per month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Weifang, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

Product Detail

| Model No.: | ESTYE-G001 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | ESTYE |

| certificate: | ISO9001:2000 |

| color: | blue and red |

| surface treatment: | powder coating spray glavanized |

| length of the arm: | 800mm |

| height: | 3000mm |

| layer: | 3 |

| material: | Q235 Steel |

| load: | 500kg to 800kg per arm |

| Production Capacity: | 5000 sets per month |

| Packing: | normal packing |

| Delivery Date: | 10 working days after the 30% deposit |

Product Description

Cantilever Pallet Storage Rack is just the ticket if you need to store long, bulky items such as: Lumber, Metal,Beams, Pipes Molding, Metal and Plastic Sheets, Tubing, Carpeting.

Name | Cantilever Racking | Material | Q235B Steel |

Size | Customized Size | Color | RAL color code |

Depth | 500mm to 1200mm | Weight Capacity | 1000kg/arm |

Width | 3000mm to 6000mm | Height | Customized |

Finish | Powder coating; Hot Dip Galvanized | ||

Packing | Export Package | ||

Certification | RMI/CE/ISO/TUV/AS4084-2012 | ||

MOQ | One 20ft/40ft Container | ||

Free Sample | Available (Delivery Cost on Buyer) | ||

OEM | Available | ||

Advantages

Systems consist of columns with one or two horizontal beams at the base to provide stability, with a series of arms attached that loads can be placed on. Rows can include both single- and double-sided cantilever. Single sided is usually placed against the wall allowing access from one side only. Double sided cantilever can be accessed from both sides.

Cantilever pallet rack systems are available in both roll formed and structural steel designs.

Patented Lok-Joint features a pin locking system that is strong, safe and adjustable. When the arm pins engage in the column slots, the connection gets stronger when the rack is loaded (within allowable limits). Arms are quickly adjustable up or down in 3" internals and can be easily removed or replaced.

Drop-in steel decks and a spring-loaded entry guide system are available for safety and protection of both merchandise and the pallet racks system.

A wide range of load capacities are available to meet your specific weight, size and space requirements.

Product can be loaded manually if light enough or by forklifts or other lifting equipment if heavy.

Cantilever pallet racks systems are available in medium and heavy-duty versions and are determined by the weight, size and height of the stored product. Their interlocking parts are easily assembled and are adaptable to meet future needs.

Space Optimization

Instead of multiple large piles of materials, products or goods spread across a single dimension, cantilever racking allows you to stack long loads, such as timber, trusses, pipes or plywood. The key comes to down to proper design before installation. While adjusting the height and arms of the racking is easy, moving the beams and bases are a bit more challenging. Be sure to include wide operating aisles for forklifts, pallet jacks and other material handling equipment.

Cantilever racking can be assembled in many different formations, most commonly up against a wall for single-sided racking, or they can be placed back to back for double-sided racking. The space between the uprights can be adjusted to fit into corner, crook or cranny in your warehouse to make the most of all available space.

The right time to use cantilever racking is when you want to increase your storage capacity significantly while making it easier for you and your workforce to handle awkwardly sized materials. Cantilever racking provides your organization with the means and methods to increase productivity, safety and the work environment as you look to grow and build your business.

FAQ

1, What is the material being used for your products?

---Mild steel Q235, Q195

2, How is the goods being packed?

---Plastic banding + Stretch film wrapped, palletized for easy loading and unloading with a standard forklift truck or pallet jack.

3, What is the payment terms I can get?

---TT or L/C at sight, DP, etc.

4, What kind of finish do you provide for your goods?

---A. Electro galvanized/Zinc plated: the zinc serves as a sacrificial anode( indoor storage)

B. Hot dip galvanized: it forms a coating of corrosion-resistant zinc(indoor/outdoor and cold storage)

C.Powder coating: a type of coating that is applied as a free-flowing, dry powder(indoor/outdoor storage)

5. What is the loading capacity?

---In general, we have a light duty(100~300kg) model, medium duty(400~800kg) model and

heavy duty(1000~1700kg) model available for your choice.

6. Which product can be used in cold storage?

---Mobile rack, wire container, and roll cage are all widely used in cold storage.

7.I like your design, but couldn't find the right model from the products list, is custom size available?

---Yes, we do custom products and projects.

8 I would like to have my own design products and qty is not that big, is it ok?

---Yes, we can go with your custom design, no matter small or big qty, however, pls understand the cost will be different.

9 I don't have drawing or picture available for the custom products, could you design it for me?

Yes, we can make the best suitable design for you but do need to know the details, such as

a) dimension b) loading capacity c)stackability d)operation environment.

10 What is the minimum quantity I can order?

--1x20'GP - qty is variable depending on the size

11 What is your average production lead time?

--2-3 weeks against formal order and deposit.

12 Do I get any guarantee from your company?

-3~10 years warranty in the case that

A) Proper handling during operation, correctly forklift handling while stacking/unstacking

B) Overloading is prohibited

C) Environment request indoor, dry and not humid circumstance, do not contact with any corrosive chemical material (for zinc plated and powder coated products, no limitation for hot-dip galvanized).