drive in rack for warehouse

| Min. Order: | 150 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 600 Sets/Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Weifang, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

Product Detail

| Model No.: | ESTYE-D022 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | ESTYE |

| Type: | Vertical Type |

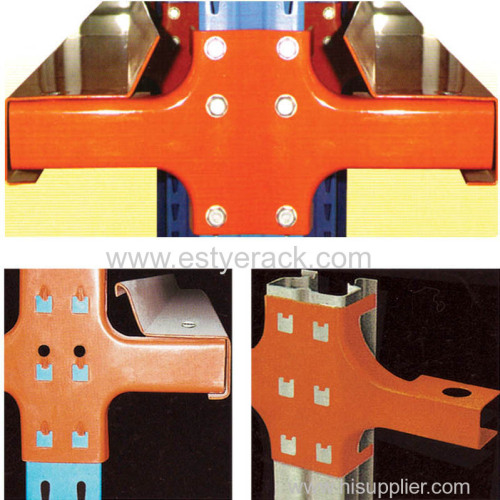

| Material: | Steel, Cold Rolled Steel Q235 |

| Feature: | Corrosion Protection |

| Use: | storage |

| Certification: | ISO9001:2000/CE/RoHS |

| Depth: | 5000-8000mm |

| Weight Capacity: | 4000kg/layer |

| Width: | 1000-1200mm |

| Height: | 6000mm |

| color: | international RAL color code |

| Production Capacity: | 600 Sets/Month |

| Packing: | 1, Standard export package 2, Carton PP film or foam |

| Delivery Date: | 15 days after 30% deposit |

Product Description

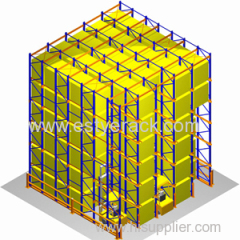

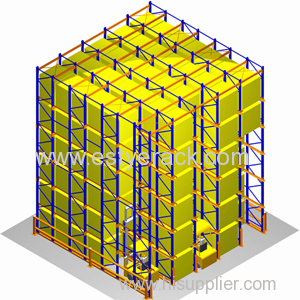

Drive in rack/racking, storage rack, warehouse rack, drive in pallet rack:

Benefits:

Maximum use of available space

Elimination of aisles between the racking.

High density racking system, with virtually unlimited depth.

No specialized fork lift trucks needed. Lless expensive than dynamic storage solutions (push-back / pallet flow).

LIFO - if stock rotation is an issue, you need to ensure that tunnels are being fully emptied before replenishing.

| Product name | Drive in Rack Type and Heavy Duty Scale pallet racking | ||

| Color | RAL system | Material | Q235B steel |

| Usage | Warehouse Storage | Certification | RMI/CE/ISO/TUV/AS4084-2012 |

| Size | Customer Size | Structure | Assembled Freely |

| height | 1350mm - 12000mm | Capacity | Max. 21000kg/bay |

| width | 900mm - 1500mm | Thickness | 1.5mm - 3.0mm |

| Style | Drive In Rack | Packing | Customers'Request |

| Brand | KINGMORE | Port | Qingdao/Nanjing/Shanghai |

Drive in rack is also called drive in pallet rack with following features:

1), Suitable for small variety but large quantity stored products, especially for standard goods;

2), Very high utility ratio of the warehouse;

3), Each aisle consists of several level of pallet support rail. Pallets are placed on pallet support rail one after another;

4), Forklifts operation alongside the aisle;

5), First-in-last-out access process, one side in/out or two side in/out can be met.

6), Top and back bracing are used to fix the whole racking, making the whole racking stable and safe;

7), first level pallets can be placed on the floor;

8), Surface treatment: powder painting;

9), Packing: Neutral paper box or in bulk or upon clients requirements;

10), Different size available;

11), Container load:10-15 ton per 1x20 container, 20-25 ton per 1x40 container

12), Delivery time: 15 days for 1x20 container, 25 days for 1x40 container

13), Payment terms: By TT or sight LC

14), MOQ: 1X20 container

Traditional pallet rack is a great solution for many warehouses, but if you have a lot ofinventory that shifts on a regular basis, drive in or drive through rack is astorage solution you may want to consider. While traditional static rackstorage allows for many rows of pallet racking with aisles between theindividual rows, drive in and drive thru racking allows for a much denserarrangement of your stored product. Both drive-in and drive through racksystems allow more efficient use of available space than traditionalmulti-aisle selective racks systems. In fact, when compared to a conventionalselective rack system, the same amount of storage can be achieved with a high density drive in or drive thru system in 80% less space.

FAQ

1, What is the material being used for your products?

---Mild steel Q235, Q195

2, How is the goods being packed?

---Plastic banding + Stretch film wrapped, palletized for easy loading and unloading with a standard forklift truck or pallet jack.

3, What is the payment terms I can get?

---TT or L/C at sight, DP, etc.

4, What kind of finish do you provide for your goods?

---A. Electro galvanized/Zinc plated: the zinc serves as a sacrificial anode( indoor storage)

B. Hot dip galvanized: it forms a coating of corrosion-resistant zinc(indoor/outdoor and cold storage)

C.Powder coating: a type of coating that is applied as a free-flowing, dry powder(indoor/outdoor storage)

5. What is the loading capacity?

---In general, we have a light duty(100~300kg) model, medium duty(400~800kg) model and

heavy duty(1000~1700kg) model available for your choice.

6. Which product can be used in cold storage?

---Mobile rack, wire container, and roll cage are all widely used in cold storage.

7.I like your design, but couldn't find the right model from the products list, is custom size available?

---Yes, we do custom products and projects.

8 I would like to have my own design products and qty is not that big, is it ok?

---Yes, we can go with your custom design, no matter small or big qty, however, pls understand the cost will be different.

9 I don't have drawing or picture available for the custom products, could you design it for me?

Yes, we can make the best suitable design for you but do need to know the details, such as

a) dimension b) loading capacity c)stackability d)operation environment.

10 What is the minimum quantity I can order?

--1x20'GP - qty is variable depending on the size

11 What is your average production lead time?

--2-3 weeks against formal order and deposit.

12 Do I get any guarantee from your company?

-3~10 years warranty in the case that

A) Proper handling during operation, correctly forklift handling while stacking/unstacking

B) Overloading is prohibited

C) Environment request indoor, dry and not humid circumstance, do not contact with any corrosive chemical material (for zinc plated and powder coated products, no limitation for hot-dip galvanized).