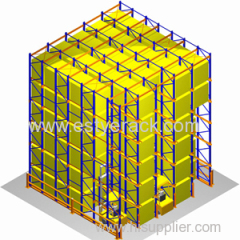

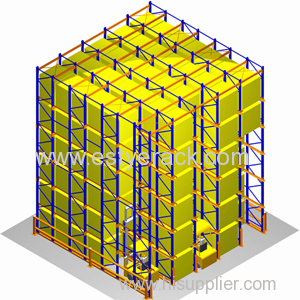

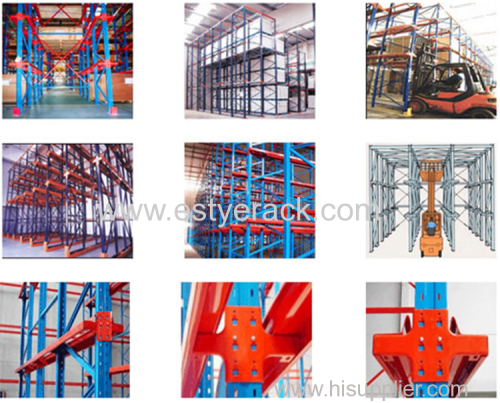

Warehouse drive in pallet racking system

| Min. Order: | 150 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 1000 Set / Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Weifang, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

Product Detail

| Model No.: | ESTYE-D019 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | ESTYE |

| Type: | Vertical Type |

| Material: | Steel, Cold Rolled Steel Q235 |

| Feature: | Corrosion Protection |

| Use: | storage |

| Certification: | ISO9001:2000/CE/RoHS |

| Depth: | 5000-8000mm |

| Weight Capacity: | 4000kg/layer |

| Width: | 800-1200mm |

| Height: | 6000mm |

| color: | on customer request |

| Production Capacity: | 1000 Set / Month |

| Packing: | 1, Standard export package 2, Carton PP film or foam |

| Delivery Date: | 15 days after 30% deposit |

Product Description

Drive-In Racks allow a lift truck to enter the rack from one side to pick up or pull out pallets. This is done because pallets can slide backwards on a continuous rail. Forklifts drive into the rack to access pallets two or more deep. You are limited in the depth of storage for a particular bay by the size of your facility. Drive-In racks are typically subject to more abuse than selective racks due to the way they are utilized, so rack integrity and strength are important factors. It is ideal rack for cooler or freezer applications.Technical Parameters of Drive in Heavy Duty Rack

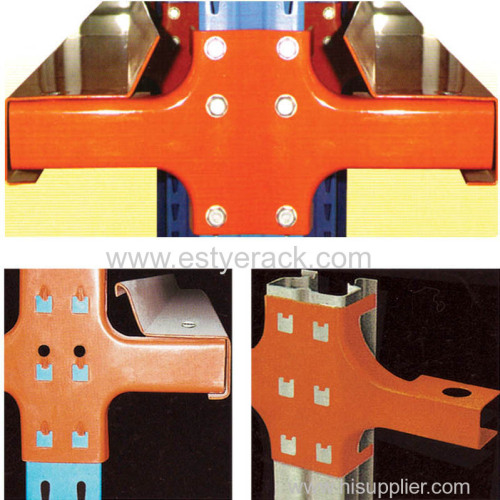

(1)Shelves use 80 * 60 * 2.0 pillar, large bearing ability,

(2) Shelves total height is 3100mm, space of holes in pillar is 75mm, adjustable, accumulative error of holes space is plus or minus 1mm,

(3) When full loading, the maximum deflection of pillar less than 1/1000H,

(4) Under static load, the safety point up to 2.0,

(5) Material: Fine steel SS4OO type

Brand name | ESTYE Rack |

Product name | Warehouse Storage Rack Use Cold Room Steel Heavy Duty Drive In Racking System |

Material | Cold-rolled Steel |

Product size | Length: 1200/1500/1800 mm |

Thickness | column:1.5mm, 2.0mm |

Load capacity | 1000-4000kg/layer |

Layers | 2-5 adjustable layers (can be custom made) |

Color | RAL color; As per customer's requirement |

Surface Treatment | Electrostatic spray surface |

Feature | Anti-rust, Corrosion-protection |

MOQ | 10sets |

Certificate | CE/ISO9001 |

Supply Ability | 5000pieces per month |

Payment Terms | 30% deposit upon signing the contract, the balance will be cleared by T/T before delivery |

Delivery Time | Within 10-35 workday upon receipt of the deposit |

| Upright size | Height (mm) | Max load for the upright frame (kg) | Beam szie |

| 55*60*1.2 | 2 | 2 | 40*60*1.5 |

| 55*60*1.5 | 4 | 4 | 40*60*1.5 |

| 55*60*2.0 | 4 | 5 | 40*60*1.5 |

| 60*70*1.8 | 6 | 5 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 60*70*2.0 | 6 | 7 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 60*80*1.8 | 6 | 6 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 60*80*2.0 | 6 | 8 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*90*1.8 | 10 | 8 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*90*2.0 | 11.5 | 10 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*100*1.8 | 11.5 | 10 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*100*2.0 | 11.5 | 12 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 |

Design, Manufacture and Installation Standard

1)The Technical Basis.

Three-dimensional storehouse of design, manufacture, installation, debugging and acceptance should follow the following standards:

GBJ - 88 Steel structure design manual

ZBJ83015-89 High shelves warehouse design standard

GB/T 5323-91 Three-dimensional storehouse steel structure shelves technical conditions

FEM9.831 European material handling association shelves design standard

GB92865-88 Electrostatic powder spraying construction standard

2) The Design Stabdard

1, High starting point, specialization, lower investment, high efficiency.

2, Adopt domestic and foreign mature three-dimensional warehouse technology, choosing pallet racking and sub-heavy shelves and supporting facilities.

3, High efficient utilization of existing space.

4, Optimized for material storage and running path, uniform averaged load, ensure material according to the shortest path mobile, access, in order to improve the operational efficiency of freely.

5, Simple operation, high automation, safe and reliable operation, convenient to fix.

FAQ:

1, What is the material being used for your products?

---Mild steel Q235, Q195

2, How is the goods being packed?

---Plastic banding + Stretch film wrapped, palletized for easy loading and unloading with a standard forklift truck or pallet jack.

3, What is the payment terms I can get?

---TT or L/C at sight, DP, etc.

4, What kind of finish do you provide for your goods?

---A. Electro galvanized/Zinc plated: the zinc serves as a sacrificial anode( indoor storage)

B. Hot dip galvanized: it forms a coating of corrosion-resistant zinc(indoor/outdoor and cold storage)

C.Powder coating: a type of coating that is applied as a free-flowing, dry powder(indoor/outdoor storage)

5. What is the loading capacity?

---In general, we have a light duty(100~300kg) model, medium duty(400~800kg) model and

heavy duty(1000~1700kg) model available for your choice.

6. Which product can be used in cold storage?

---Mobile rack, wire container, and roll cage are all widely used in cold storage.

7.I like your design, but couldn't find the right model from the products list, is custom size available?

---Yes, we do custom products and projects.

8 I would like to have my own design products and qty is not that big, is it ok?

---Yes, we can go with your custom design, no matter small or big qty, however, pls understand the cost will be different.

9 I don't have drawing or picture available for the custom products, could you design it for me?

Yes, we can make the best suitable design for you but do need to know the details, such as

a) dimension b) loading capacity c)stackability d)operation environment.

10 What is the minimum quantity I can order?

--1x20'GP - qty is variable depending on the size

11 What is your average production lead time?

--2-3 weeks against formal order and deposit.

12 Do I get any guarantee from your company?

-3~10 years warranty in the case that

A) Proper handling during operation, correctly forklift handling while stacking/unstacking

B) Overloading is prohibited

C) Environment request indoor, dry and not humid circumstance, do not contact with any corrosive chemical material (for zinc plated and powder coated products, no limitation for hot-dip galvanized).