drive in pallet rack wiht standard pallet size

| Min. Order: | 150 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,CIP,EXW |

| Payment Terms: | Paypal, L/C, D/A, T/T, WU, Money Gram |

| Supply Ability: | 1000 Sets / Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Weifang, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

Product Detail

| Model No.: | ESTYE-D014 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | ESTYE |

| Type: | Vertical Type |

| Material: | cold rolled Steel Q235 |

| Feature: | Corrosion Protection |

| Use: | storage |

| Certification: | ISO9001:2008/CE/RoHS |

| Depth: | 800-1100mm |

| Weight Capacity: | 3000kg/layer |

| Width: | 800-1200mm |

| Height: | 6000mm |

| color: | international RAL color code |

| Production Capacity: | 1000 Sets / Month |

| Packing: | 1, Standard export package 2, Carton PP film or foam |

| Delivery Date: | 15 days after 30% deposit |

Product Description

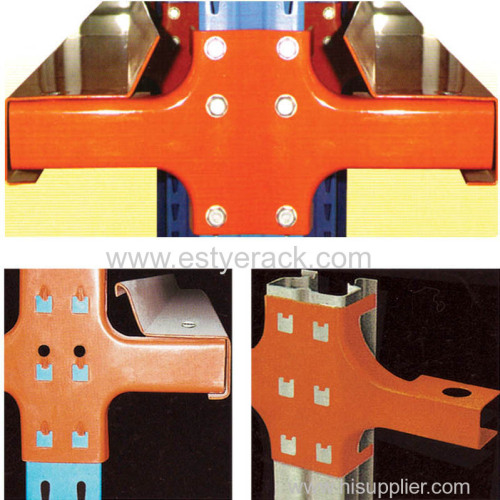

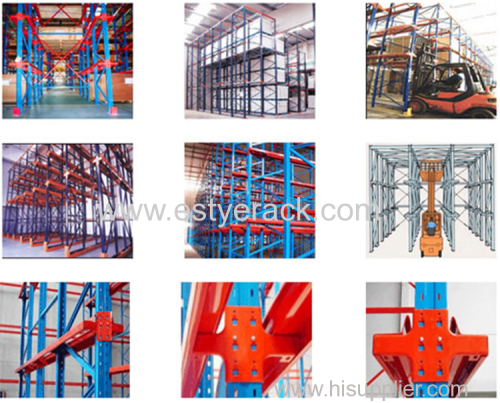

Drive in rack

Drive in rack usually uses the pallets to storage the goods.The pallets can be put on the support arm one by one in the direction of the rack.In this way,it makes the high density of the space possible.And the goods can be unload from one side of the rack with an arrangement of Last-In-First-Out(LIFO).And the fork man can drive in to lift the goods out without special rails.it is suitable for the goods of less kind and large quantity.With a inserting structure,the upright frame of the drive in rack uses the assmbled structures.The rack depth should be within five pallets if the rack is next to the wall of the warehouse.When the rack is in the center of the warehouse,the rack depth should be within 10 pallets,which can make fork man effectively and dependable.Drive in rack is widely used in the fields of cold warehouse,foods and tobacco,which needs a high cost of the storage space of the warehouse.

| Product name | Drive in Rack Type and Heavy Duty Scale pallet racking | ||

| Color | RAL system | Material | Q235B steel |

| Usage | Warehouse Storage | Certification | RMI/CE/ISO/TUV/AS4084-2012 |

| Size | Customer Size | Structure | Assembled Freely |

| height | 1350mm - 12000mm | Capacity | Max. 21000kg/bay |

| width | 900mm - 1500mm | Thickness | 1.5mm - 3.0mm |

| Style | Drive In Rack | Packing | Customers'Request |

| Brand | ESTYE | Port | Qingdao/Nanjing/Shanghai |

What are the advantages of drive-in rack?

Drive-in racks are perfect for high-density storage of similar items that can be accessed on a last-in, first out basis. These racks work well for a large quantity of similar products that move quickly in and out of inventory. When warehouse space is at a premium, drive-in racks are one of the best storage solutions on a cost-per-square-foot basis.

Drive in rack and drive through rack Characteristics

With drive-in and drive-through racking, load units are stored on the racking depth one after the other on two continuous shelves.

A loading/unloading cycle per racking field from the top to the bottom (or the other way round) must be observed during depositing and retrieval.

The trucks can drive into the racking lanes. With drive-in racking, rack servicing is only possible from one side (LIFO method). With drive-through racking in contrast, depositing can be carried out from one side and at the same time retrieval from the other side (FIFO method). Compared with drive-in racking, throughput is therefore higher with drive-through racking.

Quality and security

1. Drive in and Drive through pallet racking solutions comply with the strictest international safety standards, and also come with Racking's quality and innovation guarantee.

2. 2-year quality guarantee

The reliability of our compact pallet racking solutions means we are able to offer 5-year quality guarantees against all types of manufacturing or hidden defects in the components of the main structure of our racking solutions.

3 Pioneering component traceability system

With this system, the various above-mentioned elements have an identifying mark, which means being able to trace and document each upright without needing the package label, and therefore knowing which component it is, its design and what raw material has been used in its manufacture.

4. 100% automated production

Our industrial racking component production process is fully automated: it incorporates state-of-the-art profiling machines with a continuous cutting process and laser measurement control, welding centres and automated painting and packaging processes, which guarantee the highest quality parameters.

FAQ

Q: What's your trading terms?

1) Payment terms: T/T 30% deposit after order confirmed, 70% balance paid against bill of lading. L/C O/A also available.

2) Lead time: normally in 20-25 days after deposit received.

3) Sample policy: samples are always available for each model. Samples can be ready in 7-15 days once payment received.

4) Shipping port: Qingdao/Shanghai / Nanjing China.

5) Discounts: we offer good discount for large quantity.

Q: How I can delivery my goods?

1) Sea freight: we will update sea freight once we know your sea port where goods will be delivered.

2) Agent designated by client: please tell us the contact detail of your shipping agent and we will arrange to deliver the items.

Q: What is your service?

1) Your inquiry related to our products or price will be replied in 12 hours.

2) Well-trained and experienced staffs to answer all your inquiries in fluent English.

3) OEM & ODM, any your customized racking we can help you to design product.

4) We have very experienced professional engineers to make best solutions.

Q: What to purchase your product?

Design drawing →Confirm drawing→Quotation→PI→Confirm PI→Arrange 30%deposit→Manufacture→QC inspect→Pay balance→Shipping

Q: What's your advantage?

1) Payment: we can do O/A 40-60 days.

2) Lead time: rush order we can fast delivery.

3) Factory price: factory direct sale competitive price.

4) Warranty: Two years warranty, the broken parts will be replaced and sent to you.