storage drive in rack

| Min. Order: | 150 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DDP,DAP,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 300 Set/Sets / Month |

| Place of Origin: | Shandong |

Company Profile

| Location: | Weifang, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

Product Detail

| Model No.: | ESTYE-D008 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | ESTYE |

| Type: | Vertical Type |

| Material: | Steel, Cold Rolled Steel Q235 |

| Feature: | Corrosion Protection |

| Use: | storage |

| Certification: | ISO9001:2000/CE/RoHS |

| Depth: | 5000-8000mm |

| Weight Capacity: | 4000kg/layer |

| Width: | 800-1200mm |

| Height: | 6000mm |

| color: | international RAL color code |

| Production Capacity: | 300 Set/Sets / Month |

| Packing: | 1, Standard export package 2, Carton PP film or foam |

| Delivery Date: | 15 days after 30% deposit |

Product Description

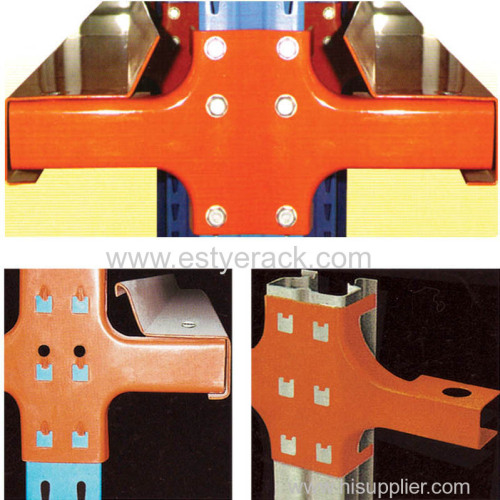

drive in rack

Traditional pallet rack is a great solution for many warehouses, but if you have a lot ofinventory that shifts on a regular basis, drive in or drive through rack is astorage solution you may want to consider. While traditional static rackstorage allows for many rows of pallet racking with aisles between theindividual rows, drive in and drive thru racking allows for a much denserarrangement of your stored product. Both drive-in and drive through racksystems allow more efficient use of available space than traditionalmulti-aisle selective racks systems. In fact, when compared to a conventionalselective rack system, the same amount of storage can be achieved with a high density drive in or drive thru system in 80% less space.

High density storage racks work by utilizing standard pallet rack uprights in conjunction with rail beams or more simply, rails to store the pallet loads in a very denseconfiguration. The key difference between these racks and selective pallet racks is that the forklift truck operates inside of the rack itself and thereare no specified lanes between the rows. The forklifts enter into the individual bays of the rack and the bays themselves can be as long or as short as needed.

Drive in rack and Drive through rack systems decrease storage and retrieval time while increasing efficiency and productivity among workers. Not only do they benefit youroperations, they can also decrease your bottom line by giving you more storage room per dollar spent on racking. Because these racks create a more uniform load in a confined storage area, your forklift operators working in the system become more skillful drivers. In addition to these benefits, consider this -drive-in & drive-thru systems are very energy efficient. Since the products so densely loaded in this type of system, there is less air to be heated or cooled between your pallets and your forklifts don't need to drive as far to pick or place loads thereby using less fuel.

Heavy Duty Drive-In Pallet Racks for High-Density Storage Drive-In Racks allow a lift truck to enter the rack from one side to pick up or pull out pallets. This is done because pallets can slide backwards on a continuous rail. Forklifts drive into the rack to access pallets two or more deep. You are limited in the depth of storage for a particular bay by the size of your facility.

| Product name | Drive in Rack Type and Heavy Duty Scale pallet racking | ||

| Color | RAL system | Material | Q235B steel |

| Usage | Warehouse Storage | Certification | RMI/CE/ISO/TUV/AS4084-2012 |

| Size | Customer Size | Structure | Assembled Freely |

| height | 1350mm - 12000mm | Capacity | Max. 21000kg/bay |

| width | 900mm - 1500mm | Thickness | 1.5mm - 3.0mm |

| Style | Drive In Rack | Packing | Customers'Request |

| Brand | ESTYE | Port | Qingdao/Nanjing/Shanghai |

Drive-In racks are typically subject to more abuse than selective racks due to the way they are utilized, so rack integrity and strength are important factors. It is ideal rack for cooler or freezer applications.This is a last-in, first-out arrangement for your pallets Drive-In & Drive-Through Racks offer the ability to store a large amount of similar loads in a smaller area. Selectivity is sacrificed, but storage density is outstanding. Drive In Racking can store up to 75% more pallets in the same space than selective racking -- depending on your application. It requires fewer aisles and is better cubic storage.

Drive-In Rack is used to store many pallets of a similar SKU or product. Lift trucks drive into the rack to extract the first pallet they come to. This is "Last-In, First-Out" storage.

Drive-In racks:

Drive-In racks are designed for heavy-duty high density storage. They allow a lift truck to enter the rack to pick-up or pull out pallets. Drive-In pallet racking allows the flexibility to store large amounts of similar items in a small area.

FAQ

Q: What's your trading terms?

1) Payment terms: T/T 30% deposit after order confirmed, 70% balance paid against bill of lading. L/C O/A also available.

2) Lead time: normally in 20-25 days after deposit received.

3) Sample policy: samples are always available for each model. Samples can be ready in 7-15 days once payment received.

4) Shipping port: Qingdao/Shanghai / Nanjing China.

5) Discounts: we offer good discount for large quantity.

Q: How I can delivery my goods?

1) Sea freight: we will update sea freight once we know your sea port where goods will be delivered.

2) Agent designated by client: please tell us the contact detail of your shipping agent and we will arrange to deliver the items.

Q: What is your service?

1) Your inquiry related to our products or price will be replied in 12 hours.

2) Well-trained and experienced staffs to answer all your inquiries in fluent English.

3) OEM & ODM, any your customized racking we can help you to design product.

4) We have very experienced professional engineers to make best solutions.

Q: What to purchase your product?

Design drawing →Confirm drawing→Quotation→PI→Confirm PI→Arrange 30%deposit→Manufacture→QC inspect→Pay balance→Shipping

Q: What's your advantage?

1) Payment: we can do O/A 40-60 days.

2) Lead time: rush order we can fast delivery.

3) Factory price: factory direct sale competitive price.

4) Warranty: Two years warranty, the broken parts will be replaced and sent to you.

Q: Does estyeracking have MOQ (minimum order quantity) limitation?

A: No, but good quantity comes with good price. We recommend the order quantity for regular products of estyeracking to fit at least one 20ft. container, which is about 15 tons.

Q: How does estyeracking charge tooling fee (cost of opening new mold)?

A: For the production of necessary tooling requirement, estyeracking charges the cost before the first order for opening new mold, and the cost will be partially or fully refunded after certain quantity of orders.

.jpg)