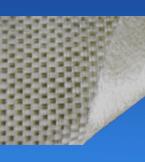

Fiberglass Needle Mat

| Place of Origin: | Jiangxi |

|---|

Company Profile

| Location: | Jiujiang, Jiangxi, China (Mainland) |

|---|

Product Detail

| Model No.: | FM-N00A |

|---|

Product Description

Introduction

E-glass needle mat is a new fiberglass reinforcement product. The needle mat is made from continuous fiberglass strands randomly looped and laid on a roving matrix, then needle stitched together. Needle Mat is primarily used in fiberglass molding processes such as GMT, RTM, etc. Typical products are automotive running boards, architectural panels, large industrial panels and other FRP products.

Product Characteristics

1. No binder or other knitting material used to bond the mat together.

2. Good resin flowability. Quick wet through. No white strands.

3. Strand has good resistance to washability and suitable for RTM and other molding processes.

4. The mat is not easy to cut, therefore the mat is suitable for thick molded components.

5. Needle mat easily fills the mold and conforms to complex shapes, while providing a smooth finished surface.

Technical Specifications

R2O Content <0.8%

Coupling Agent Silane

Moisture Content ≤0.2%

Fiber Diameter 13μm or 21μm

*Standard mat widths are 1460 mm and 1500 mm. Special products are available according to customer's requirements.

Packaging

Needle Mat products are rolled around a mandrel with an inside diameter of 7.6 cm. Roll diameter is 30 cm. Rolls are wrapped in plastic bags, then packed in cardboard boxes. Individual rolls weigh between 15 kg and 20 kg. There are 12 boxes vertically packed on a 96cm′128cm pallet, which is shrink-wrapped with plastic film?

E-glass needle mat is a new fiberglass reinforcement product. The needle mat is made from continuous fiberglass strands randomly looped and laid on a roving matrix, then needle stitched together. Needle Mat is primarily used in fiberglass molding processes such as GMT, RTM, etc. Typical products are automotive running boards, architectural panels, large industrial panels and other FRP products.

Product Characteristics

1. No binder or other knitting material used to bond the mat together.

2. Good resin flowability. Quick wet through. No white strands.

3. Strand has good resistance to washability and suitable for RTM and other molding processes.

4. The mat is not easy to cut, therefore the mat is suitable for thick molded components.

5. Needle mat easily fills the mold and conforms to complex shapes, while providing a smooth finished surface.

Technical Specifications

R2O Content <0.8%

Coupling Agent Silane

Moisture Content ≤0.2%

Fiber Diameter 13μm or 21μm

*Standard mat widths are 1460 mm and 1500 mm. Special products are available according to customer's requirements.

Packaging

Needle Mat products are rolled around a mandrel with an inside diameter of 7.6 cm. Roll diameter is 30 cm. Rolls are wrapped in plastic bags, then packed in cardboard boxes. Individual rolls weigh between 15 kg and 20 kg. There are 12 boxes vertically packed on a 96cm′128cm pallet, which is shrink-wrapped with plastic film?

.jpg)