.jpg)

high precision OEM steel hardware parts processed by forging casting and cnc machining

0.5~10.0 USD

| Min. Order: | 10000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5,000,000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Precision Sheet Stamping Part, Lost Wax Investment Casting, Hydraulic Hose Pipe Fitting, Bearing Rubber Seals, Silicone Oil Seal |

Product Detail

| Model No.: | FW004 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | no |

| Specification: | machined hardware parts |

| Function: | industrial components |

| Quality system: | ISO9001:2008 |

| Export Area: | Europe;USA |

| Process: | forging,casting,cnc machining,heat treatment |

| Surface: | anti rust protection,plating,anodizing,coating |

| Material: | carbon steel, ss steel,brass,aluminium |

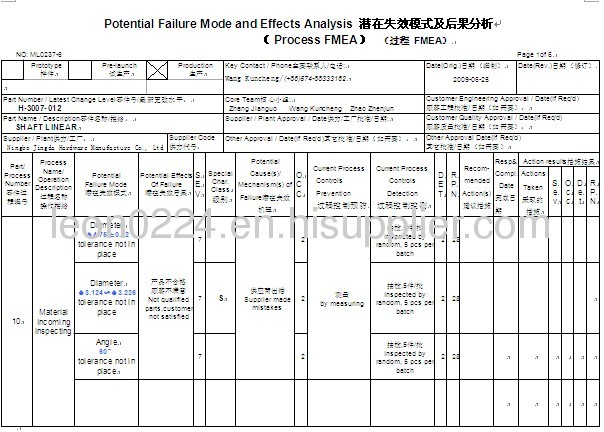

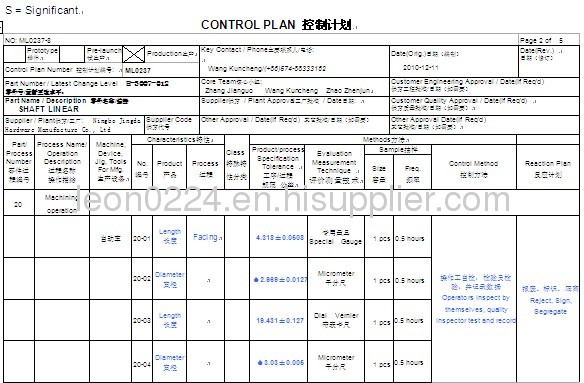

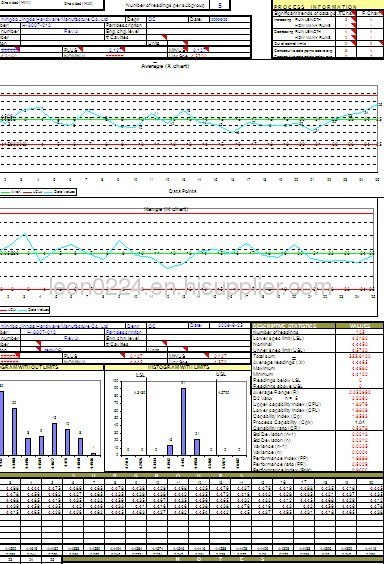

| Paper work: | PPAP |

| Export port: | Ningbo |

| Production Capacity: | 5,000,000 |

| Packing: | standard export packing |

| Delivery Date: | 30Days |

Product Description

Products: OEM CNC turning hardware parts

Decription:there are parts made in all kinds of metals,such as carbon steel AISI 1010,1020,1045,SAE1040,

4140,4340, mild steel,easy cutting steel 1214,12L14,1215,stainless steel AISI303,304,316, 316L,

aluminium 6160,copper or brass...

Main processes: forging or casting, machining(turning,milling or grinding), surface treatment(plating) or

heat treatment, anti-rust protection.

Machines available: lather,cnc lather,cnc milling, grinder, cnc center, wire cutting,

Quality control faclities:CPJ-300 projector, HR-150DT hardness, TR200 roughness test, EV2515 projector,

VMT250 projector, Height meter,Concentricity tester,Runout meter, VA-640 micro-Vikers hardness

tester,etc.

Application: they are widely used in all industrial,such as machinery,aerospace,sanitation,automobile...

Tolerance: depends on drawing requirements, the highest tolerance we're doing is 0.005mm.Decription:there are parts made in all kinds of metals,such as carbon steel AISI 1010,1020,1045,SAE1040,

4140,4340, mild steel,easy cutting steel 1214,12L14,1215,stainless steel AISI303,304,316, 316L,

aluminium 6160,copper or brass...

Main processes: forging or casting, machining(turning,milling or grinding), surface treatment(plating) or

heat treatment, anti-rust protection.

Machines available: lather,cnc lather,cnc milling, grinder, cnc center, wire cutting,

Quality control faclities:CPJ-300 projector, HR-150DT hardness, TR200 roughness test, EV2515 projector,

VMT250 projector, Height meter,Concentricity tester,Runout meter, VA-640 micro-Vikers hardness

tester,etc.

Application: they are widely used in all industrial,such as machinery,aerospace,sanitation,automobile...

Quality control flow: material in, inspection,lable and record;

mateiral storage and distribution, lable and record;

process and supervise according to Control Plan at operation spot;

randem quality inspection by QC

quality inspection in quality department before putting in warehouse

Process FMEA

Part Submission Warrant

Process Flow Diagram

Control Plan

if CPK analyse required,

Packing: OEM CNC turning hardware parts/carton/wood pallet

Lead time: 20days for initial samples or prototype

30-40days for first regular purchasing order

20days from the second orders