rough parts forged/grinding and boring round steel spacer with high precision/automobile components

0.5~1.0 USD

| Min. Order: | 10000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/A, T/T |

| Supply Ability: | 200000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Precision Sheet Stamping Part, Lost Wax Investment Casting, Hydraulic Hose Pipe Fitting, Bearing Rubber Seals, Silicone Oil Seal |

Product Detail

| Model No.: | FA-10 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Specification: | spacer bushing |

| Function: | industrial components |

| Quality system: | ISO9001:2008 |

| Export Area: | all over the world |

| Material: | Carbon steel aisi 1045 |

| Process: | Grinding, boring, turning |

| Surface: | anti-rust protection |

| Paper work: | PPAP |

| Port of loading: | Ningbo or Shanghai |

| Production Capacity: | 200000 |

| Packing: | carton/wooden pallet |

| Delivery Date: | 30days |

Product Description

Product: round steel spacer

Material: AISI 1045 high carton steel

Process: rough parts forging, cnc turning,grinding and boring

Machines: meter lathe, cnc lathe(50 sets),cnc centers,centreless grinding

maching, cylindrical grinding machine,cnc milling machine,stamping

machine.

Heat treatment: caburizing hardened

Surface: anti-rust protection, antirust preservation oil, zinc or nickel plated

Documentation: PPAP as TS14969

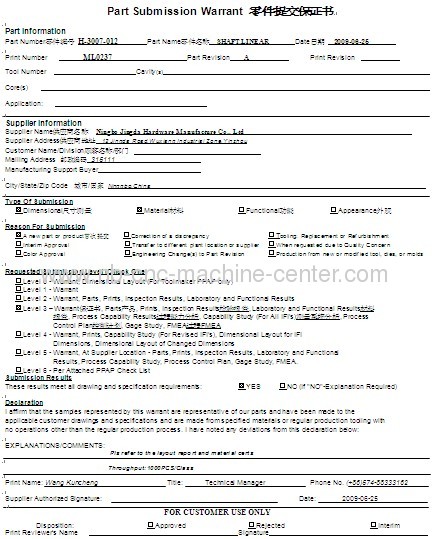

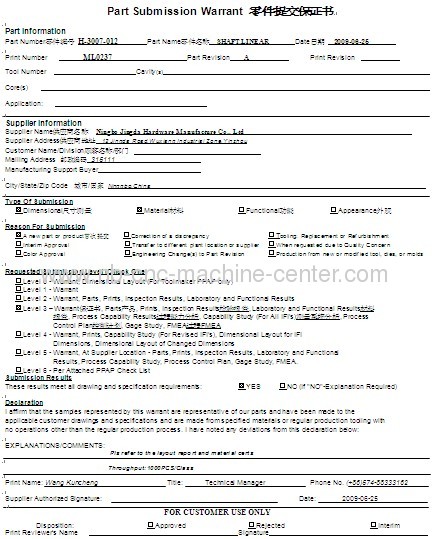

Part submission warrant

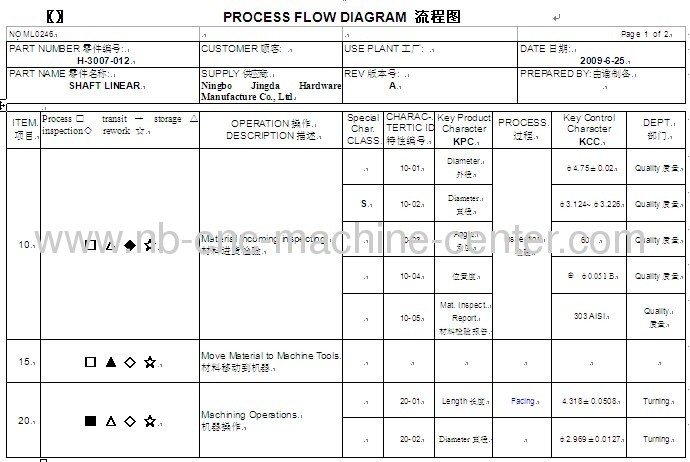

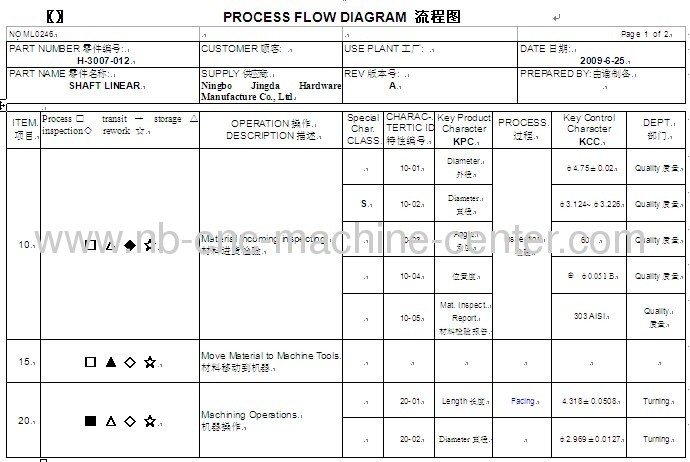

Process Flow Diagram

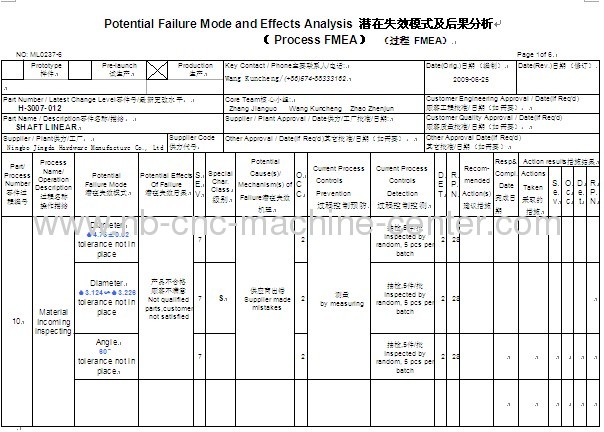

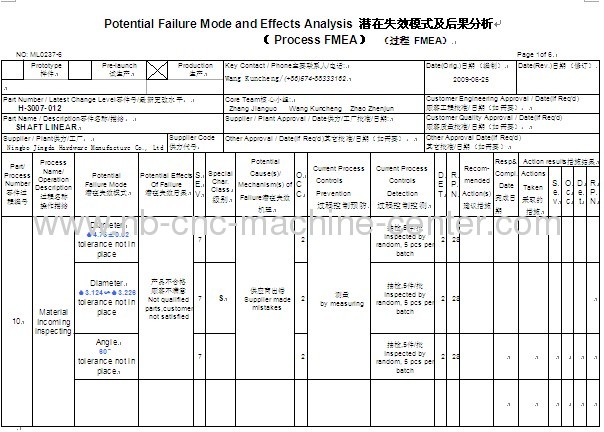

Potential Failuar Mode and Effects Analysis-PROCESS FMEA

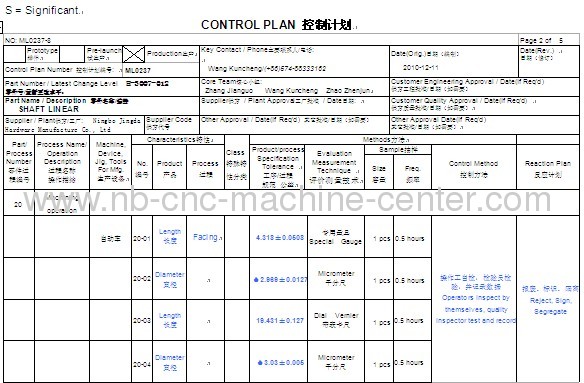

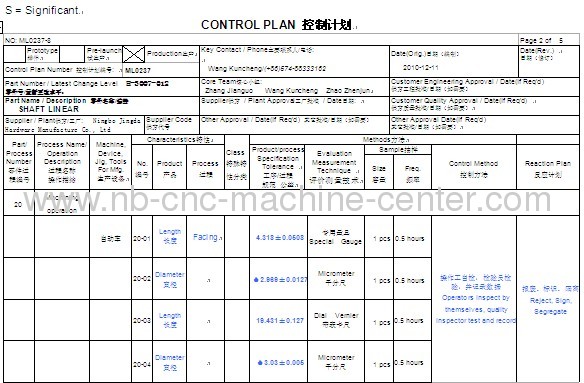

Control Plan

Material: AISI 1045 high carton steel

Process: rough parts forging, cnc turning,grinding and boring

Machines: meter lathe, cnc lathe(50 sets),cnc centers,centreless grinding

maching, cylindrical grinding machine,cnc milling machine,stamping

machine.

Heat treatment: caburizing hardened

Surface: anti-rust protection, antirust preservation oil, zinc or nickel plated

Documentation: PPAP as TS14969

Part submission warrant

Process Flow Diagram

Potential Failuar Mode and Effects Analysis-PROCESS FMEA

Control Plan