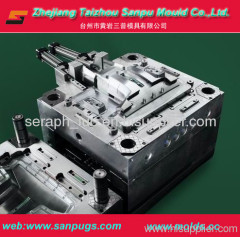

auto lamp plastic mould

10000.0~150000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Agent, Service |

| Main Products: | Plastic Mold Mould Injection, Plastic Injection Molding Machine, Injection Moulding Machine PET, Pet Perform Mould, Perform Mould |

Product Detail

| Means of Transport: | Ocean |

|---|---|

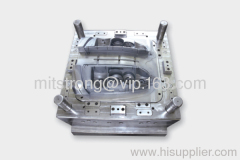

| Product: | Vehicle Mould |

| Product Material: | Steel |

| Shaping Mode: | Plastic Injection Mould |

| Brand Name: | Mitstrong |

| Production Capacity: | 200 |

| Packing: | wooden cases |

| Delivery Date: | 60~90 |

Product Description

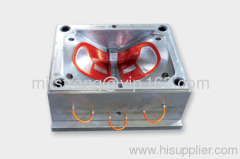

Exterior Trim Parts Mould, Bumper Mould, Grille Mould, Air Spoiler Mould, Side trim mould, Shock Absorber Mould, Fender protector mould, Other auto plastic mould, Interior Parts Mould, Instrument Panel Mould, door trim mould, Glove box mould, Console Box Mould, Cup holder mould, Column Cover Mould, Lateral Dash Board Mould, Airbag Switch Cover Mould, Steering Wheel Mould, Air Ventilator Plastic Injection Mould, Lighting System Mould, Front Lamp Mould, Rear Lamp Mould, Side Lamp Mould, Fog Lamp Mould

Product Description

Plastic auto rear lamp mould/mold, auto tail lamp mold

Processing capacity: Mold design, mold making and plastic injection molding

Material of Mould, 45#, P20, 718, 718H, 2738, 2316, S136 and more kinds of material you can choose,

Mould frame: 45Pre-hardened>30 HRC

Cooling System: Recirculating

Medium-term treatment: Tone quality, improve the hardness

Post-processing: Nitride(Nitriding temperature is low, deformation is small, it is no longer the need for quenching high surface hardness(over HV850) and wear

Die life: P20 Normal use no less than 30 million times

Molding process technology: Review plan--- Stock preparation--- Processing-- Rough mold base --- Punch machining--- EDM die sinking--- Die Machining---Inspection--- Assembly--- Flight mode--- Tryout--- Customer confirm the sample--- producer of delivery to the customer

Transportation: In the mold must be installed before shipment clamping piece, packing strong, rust-proof, logistics and transport

After-sales service: Die 1 year repair, Free maintenance during warranty

Note: Mold in the production process, we have to offer die each week of progress and take pictures