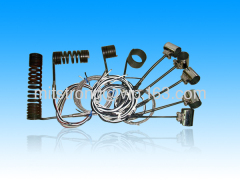

spare parts for PET preform moulds

1500.0~3500.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Taizhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Agent, Service |

| Main Products: | Plastic Mold Mould Injection, Plastic Injection Molding Machine, Injection Moulding Machine PET, Pet Perform Mould, Perform Mould |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Product: | Household Appliance |

| Product Material: | Steel |

| Shaping Mode: | Plastic Injection Mould |

| Brand Name: | Mitstrong |

| Type: | Packing industrial molds |

| Production Capacity: | 200 |

| Packing: | wooden cases |

| Delivery Date: | 30~70 |

Product Description

| 1. | Mold cavity from 1 up to 72. |

| 2. | With hotter runner and air sealed structure, you needn't bother with the annoying tails any more. Since the tail is within 1mm. You can use the preform into blowing directly. |

| 3. | Cavity and Core are made from S2316 steel to guarantee mold's high precession. |

| 4. | Digital Control Lathe, EDM, jig-boring machine and high-precision grinding machine have been used on mold building for precision. |

| 5. | Balanced cooling channel provide bright transparency to preform. |

| 6. | Carry out self-lock structure for each cavity independently to prevent the final preform from eccentricity problem. |

| 7. | Off-center Adjustment System ensure the preform with less eccentricity (less 0.1mm) |

| 8. | Preform mold life reach 1,000,000 shots. |

PET preform mould steel

PET preform mould core steel: STAVAXS420 stainless steel, tempered with HRC 50+/-2

PET preform mould cavity steel: STAVAX S420 stainless steel , tempered with HRC 50+/-2

PET preform mould neck screw steel : DIN 1.2083 with tempered HRC45

PET preform mould base steel: DIN 1. 2311 with grinding machine with each plate thickness tolerance 0.015mm for a plate size 500*500*40mm with HRC 32

PET preform mould spare parts steel: DIN 1.2344 dimension measure up to D-M-E matric standard

.jpg)

.jpg)

.gif)