Foundry consumable ceramic foam filter

| Min. Order: | 10000 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Place of Origin: | Hebei |

Company Profile

| Location: | Baoding, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Filter Mesh, Filter Mesh For Filtration, Fiberglass Filter |

Product Detail

| Means of Transport: | Ocean |

|---|

Product Description

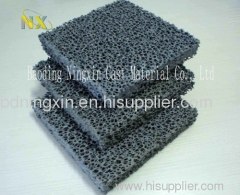

Silicon carbide ceramic foam filters of NINGXIN are designed to improve the quality of nodular, grey, and malleable iron castings. They effectively removenon-metallic inclusions including slag and dross from the molten metal stream. Additionally, they aid in reducing turbulence in the gating system. Their outstanding thermal shock resistance and high strength properties were developed for superior performance in extreme iron foundry applications.

· Clean iron castings

· Increased casting yield

· Fewer inclusions

· Real cost savings from significant

-reduction in scrap caused by:

-in-house gross slag defects

-after-machining sub-surface defects

-final component leakers and blow holes

· Consistent pour times

· Increased casting yield

· Fewer inclusions

· Real cost savings from significant

-reduction in scrap caused by:

-in-house gross slag defects

-after-machining sub-surface defects

-final component leakers and blow holes

· Consistent pour times

Mode:NX-PTW-T

Products confirm with China National Standard GB/T 25139-2010.

Products confirm with China National Standard GB/T 25139-2010.

Technical Data

Material:Silicon Carbide

Aplied Temp.(℃):≤1500

Color:Gray-black

Hole density (PPI):4-60(PPI=pore per inch)

Porosity(%):80-90

Bending stength(Mpa:0.8

Compressive Strength(MPa):≥1.0

Bulk Density(g/cm3):0.36-0.50

Thermal shock resistance:6times/1100℃

High temperature bending strength(1200℃)MPa:≥0.4

Application:Molten Iron,copper and?alloy

Material:Silicon Carbide

Aplied Temp.(℃):≤1500

Color:Gray-black

Hole density (PPI):4-60(PPI=pore per inch)

Porosity(%):80-90

Bending stength(Mpa:0.8

Compressive Strength(MPa):≥1.0

Bulk Density(g/cm3):0.36-0.50

Thermal shock resistance:6times/1100℃

High temperature bending strength(1200℃)MPa:≥0.4

Application:Molten Iron,copper and?alloy

Common specification

Round shape:

40x11mm, 40x15mm, 50x15mm, 50x20mm, 60x22mm, 70x22mm, 80x22mm , 90x22mm,100x22mm, 305x25mm

Square shape:

40x40x11mm, 40x40x15mm, 50x50x22mm, 75x75x22mm, 50x75x22mm, 100x75x22mm, 100x100x22mm, 55x55x15mm, 150x150x22mm

Round shape:

40x11mm, 40x15mm, 50x15mm, 50x20mm, 60x22mm, 70x22mm, 80x22mm , 90x22mm,100x22mm, 305x25mm

Square shape:

40x40x11mm, 40x40x15mm, 50x50x22mm, 75x75x22mm, 50x75x22mm, 100x75x22mm, 100x100x22mm, 55x55x15mm, 150x150x22mm

Varies of shape,size and PPI are available as per request.

Chemical Composition

Al2O3 SiC SiO2 Fe2O3

≤28.00% ≥62.00% ≤10.00% ≤0.50%

≤28.00% ≥62.00% ≤10.00% ≤0.50%