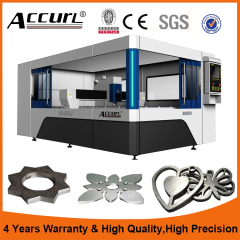

CNC laser cutter for stainless steel

3000.0~10000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5000sets/year |

| Place of Origin: | Hubei |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | GJMSJG -130250DB |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Goldenlaser |

| Laser type:: | YAG Lamp pump |

| Laser power: | 500W |

| Working area: | 1300*2500 |

| Working table: | net saw-teeth work table |

| Production Capacity: | 5000sets/year |

| Packing: | wooden package |

| Delivery Date: | 15 workdays |

Product Description

Product Features:

1,Equips with medium power lamp pump laser, flexible cutting any design within working area 1300mm*2500mm

2,Use the totally enclosed contour design, the environmental protection, the security, artistic, conforms to the CE standard.

3,With following dynamic focus system

4,With ball units machine working table

Advantage:

1) Especially for the thin metal plate specially large area cutting

2) Environmental protection, CE standard.

3) Realized different thickness materials automatic focus cutting.

4) Greatly save the manpower.

Main technical parameters:

Laser type: YAG Lamp pump

Laser power: 500W

Working area: 1500mm*3000mm

Working table: net saw-teeth work table

Repeating location:+-0.1mm

Moving system: offline CNC system, servo motor, precision ball screw drive

Standard collocation: Following focus, 550W following bottom exhaust

Select collocation: 650 lamp pump1, about 8mm cutting thickness, smooth cutting surface, less dross, the most thickness of cutting up to 10mm, which is the thickest in the small and medium-power industry of the YAG.

2, stainless steel within 6 mm, carbon steel can be used for the air-cutting in 8mm, which is not only cutting effectively, but save the cost with the maximum.

3, you can achieve the different shape and specification of parts range automatically by the best way, and enjoy the most effective cutting line by independent research and development software of Goldenlaser, After the improvement, you can save material up to 8% -10% than the general process.

4, the high efficient camera system of JinYun metal laser cutting system could achieve precise automatic positioning of sheet metal cutting process.

5, Goldenlaser owns the intelligent typesetting system that can take advantage of reusage of the corner diagonal materials once again.

6, the first integrated marking system in the industry makes the marking and cutting process perfectly realized in the same piece of equipment, maximizing the effectiveness.

2, stainless steel within 6 mm, carbon steel can be used for the air-cutting in 8mm, which is not only cutting effectively, but save the cost with the maximum.

3, you can achieve the different shape and specification of parts range automatically by the best way, and enjoy the most effective cutting line by independent research and development software of Goldenlaser, After the improvement, you can save material up to 8% -10% than the general process.

4, the high efficient camera system of JinYun metal laser cutting system could achieve precise automatic positioning of sheet metal cutting process.

5, Goldenlaser owns the intelligent typesetting system that can take advantage of reusage of the corner diagonal materials once again.

6, the first integrated marking system in the industry makes the marking and cutting process perfectly realized in the same piece of equipment, maximizing the effectiveness.

2, you could attend free various technical training courses since the date of purchase.

3, we would response in 10 hours for foreign clients and reply to make maintenance services within 72 hours.