ZG Series Chain Grate Biomass Power Station Boiler

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 Set/Sets per Year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | Waste Heat Boiler, Carbon Kiln Waste Heat Boiler, Boilers, Glass Kiln Waste Heat Boiler, Boiler |

Product Detail

| Model No.: | ZG series |

|---|---|

| Means of Transport: | Ocean |

| Fuel: | biomass fuel |

| Output: | rated evaporation:20-75t/h |

| Usage: | power station |

| Structure: | water tube |

| Pressure: | medium or high pressure |

| Style: | vertical |

| Type: | natural circulation |

| Production Capacity: | 50 Set/Sets per Year |

| Packing: | standard export package |

| Delivery Date: | 4 months |

Product Description

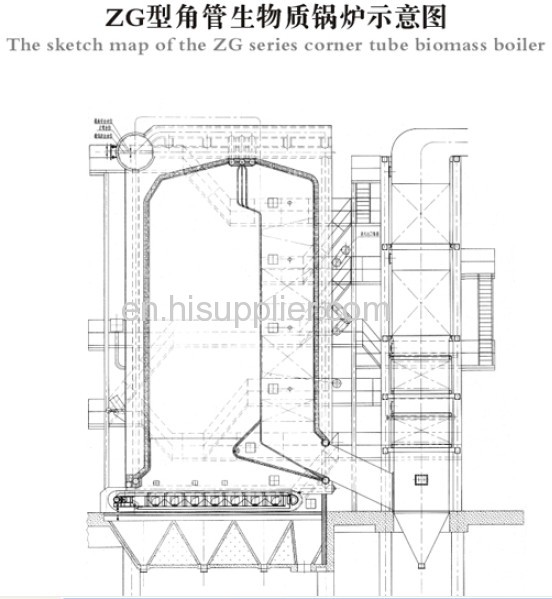

ZG Series Chain Grate Biomass Power Station Boiler is a new type field assemble chain grate boiler, which is similar with SHL series chain biomass boiler by structure. The relevent measures has been taken in Furnace, secondary air, heating surface, soot blower. ZG Series Chain Grate Biomass Power Station Boiler has all structual features of SHL series chain grate biomass boilers.

ZG Series Chain Grate Biomass Power Station Boiler uses biomass fuel such as bulk straw or stalks.The size of the fuel should be less than 50x30x10mm(length x width x thickness) or diameter30 x 50mm for clavate fuel with allowing little of those whose length is in the range of 50-100mm.The total moisture to the fuel is no greater than 25%,but the max total moisture must be less than 30%.For the pressing shaped fuel,the size of it should be no greater than 30 x30x 10mm,while the total moisture should be no greater than 15%within the general requirements.

The feature of the ZG Series Chain Grate Biomass Power Station Boiler are as following:

1. ZG Series Chain Grate Biomass Power Station Boileradopts corner tube pattern, self-supporting structure, the problem relating to the expansion and the supporting of the boilers are tackled smartly. The supporting structure is stable and compact.

2. The furnace and the descending fuel gas duct adopts total welding membrane water cool tubes wall structure, which has the features of good sealing, less heat lost and little pollution.

3. Both the air pre-heater and the economizer adopt case pattern structure, which can ensure them be transported in package, so the installation time can be saved and sealability of the fuel gas duct is strengthened.

4. There is flag pattern heating surface before the high temperature super heater, so the high temperature ability of the super heater can be ensured, meanwhile, the super heater can be operated in the serious fuel gas environment stabely.

5. The crossgrider grate is adopted, so it has the features of less operation resistance, better grate cooling effects, lower breakdown rate, less fuel leak. And the grates are made by the first-class professional manufacture.

6. The fuel is sprayed to the furnace, which can ensure the straticulating combustion and suspending combustion, thus the combustion efficiency is enhanced.

7. ZG Series Chain Grate Biomass Power Station Boiler adops sectional boiler setting so that the total weight of the boiler is lighter.