SHL Series Field Assemble Chain Grate Boiler

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 Set/Sets per Year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | Waste Heat Boiler, Carbon Kiln Waste Heat Boiler, Boilers, Glass Kiln Waste Heat Boiler, Boiler |

Product Detail

| Model No.: | SHL series |

|---|---|

| Means of Transport: | Ocean |

| Fuel: | coal or biomass fuel ,mixture of coal and biomass |

| Output: | steam: rated evaporation:10-35 t/h,hot water:rated heat output:7-28MW |

| Usage: | Industrial |

| Structure: | water tube |

| Pressure: | low pressure |

| style: | vertical |

| type: | natural /forced circulation |

| Production Capacity: | 50 Set/Sets per Year |

| Packing: | standard export package |

| Delivery Date: | three months |

Product Description

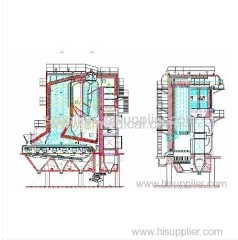

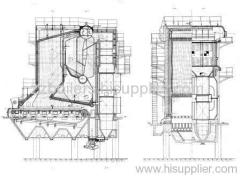

SHL Series Field Assemble Chain Grate Boiler is developed by Zhengzhou Boiler, which adopted the latest combustion theory product of Xi'an Jiao tong University. This is the fourth generation of chain grate boiler. SHL Series Field Assemble Chain Grate Boiler has the features of high power output, high combustion efficiency, stable operation, wide range of overload adjustment, can be adjusted to many kinds of coals, energy saving, environment-friendly and so on.

1. SHL Series Field Assemble Chain Grate Boiler adopts widthwise layout double drums structure, which totally overcomes the phenomenon of bulge by directly heating the drum in the furnace. The layout of the heating surface is more reasonable.

2.The two sides of furnace adopt membrane water wall structure which can ensure the seal ability of the furnace and higher the boiler efficiency as well.

3.In the heating surface of the SHL Series Field Assemble Chain Grate Boiler convection bank and the economizer, there are junctions of dust blower reserved. To some special material (especially the strong caking fuel), necessary measures can be adopted, to avoid the corresponding problems.

4.It adopts the latest arch research product of Xi'an Jiaotong University, downside "a" type arch technology, the fuel combustibility is improved and it can adjusted itself to many kinds of coal.

5.The arch adopts water cool structure, which can improve both the rigidity and the reliability of the arch, and the service life is extended.

6. SHL Series Field Assemble Chain Grate Boiler adopts GEF's improved appropriative slag removal technology. The grate adopts new type small flake type, in addition, the unique safety ring is adopted, all these add up, totally overcome the problem of the grate flakes falling off, and reduce the air leak efficiently, so that the grate can be operated stably and the combustion efficiency is greatly improved.

7.The grate adopts double sides wind feed, separate air chambers, which can meet the requirements of the combustion of the fuel efficiently.

8.It adopts two times wind structure, the aerodynamic field in the furnace is improved effectively. The heated particles of the fuel are threw to the front arch, which is propitious to the ignition of the fuel, at the same time, the fuel is kept in the furnace in a longer time, so that the adjustment and the utilization rate of the fuel is improved.

9.The boiler grate adopts double layers or single layer layout structure, which can meet the customers' requirements better.