Industrial Water-cooling Wall of Boiler

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Set/Sets per Year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | Waste Heat Boiler, Carbon Kiln Waste Heat Boiler, Boilers, Glass Kiln Waste Heat Boiler, Boiler |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Fuel: | Coal-fired |

| Output: | Steam/Hot Water |

| Usage: | Industrial |

| Structure: | Water/fire Tube |

| Pressure: | Low Pressure |

| Production Capacity: | 100 Set/Sets per Year |

| Packing: | standard export package |

| Delivery Date: | 3 months |

Product Description

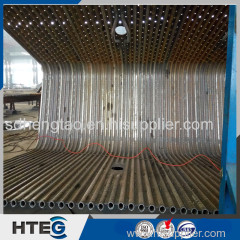

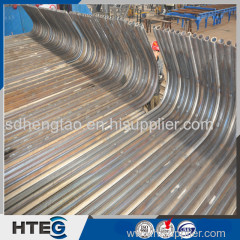

Industrial Water-cooling Wall of Boilers:Boiler uses Membrane Water-cooling Wallwich has the features of small occupation, bigger output.

Double Wings Gas Ducts structure. Boiler uses Membrane Water-cooling Wall wich has the features of small occupation, bigger output, quick pressure .

Industrial Water-cooling Wall of Boilers This boiler with Membrane Water-cooling Wall is steam boiler of horizontal type, single drum with traveling

chain grate.Industrial Water-cooling Wall of Boilers The threaded gas pipe is inside the boiler drum, and both side water-cooling wall rounds thumb flue in drum's belly. Industrial Water-cooling Wall of BoilersThis structure protects effectively the boiler drum and avoids the belly directly radiated by fire. Boiler drum connects the two headers by two side water cooling wall. Industrial Water-cooling Wall of Boilers Four downcast pipes are foreside and rearward of boiler drum, and every pipe is led from drum to header. By this design, Industrial Water-cooling Wall of Boilers the drum and headers becomes a circulation loop together with the two sides water-cooling walls.

chain grate.Industrial Water-cooling Wall of Boilers The threaded gas pipe is inside the boiler drum, and both side water-cooling wall rounds thumb flue in drum's belly. Industrial Water-cooling Wall of BoilersThis structure protects effectively the boiler drum and avoids the belly directly radiated by fire. Boiler drum connects the two headers by two side water cooling wall. Industrial Water-cooling Wall of Boilers Four downcast pipes are foreside and rearward of boiler drum, and every pipe is led from drum to header. By this design, Industrial Water-cooling Wall of Boilers the drum and headers becomes a circulation loop together with the two sides water-cooling walls.

During running, high temperature gas and ash come into soot separator from smokestack of rear arch blocking-smoke wall, then from thumb flue to front smoke chamber, then to threaded gas pipe passing single pass scour flue, finally through rear smoke box to tail flue.

Boiler heat surface includes four parts: boiler furnace radiation heat surface (right and left water-cooling wall), first bank of tubes convection heat surface, second bank of tubes convection heat surface, tail heat surface (economizer)

NO. | Method | Function | Aim |

| 1 | Single Pass Threaded Gas Tube | Remove welding thermal stress of tube end from double pass | Prevent breakage of tube-plate |

| Improveflexibility | Prevent breakage of tube-plate | ||

| The tube water side scale-forming iseasy to drop, improve gas disturbance, strengthen heat transmission | Improveheat efficiency | ||

| Nofouling, no need soot blowing | Improveheat efficiency | ||

2 | Thumb gas duct | Reduceinlet gas temperature of high-temp tube-plate Reducewelding thermal stress of tube-plate | Prevent the breakage of front tube-plate |

| Reduce heat loading of drum bottom, strengthendisturbance of drum bottom, prevent accumulation of dust | Prevent drum protruding | ||

3 | Arch Tube-plate | Improveflexibility, Remove welding thermal stress of tube end | Prevent breakage of tube-plate |

4 | Big size down comer | Reduce resistance of downcomer, improver water speedof ascending pipe, the water circulation is more reliable. | Preventbreakage of tubes |

5 | Gas and dust separation in boiler | Separate gas and dust | Reduce smoke concentration |

6 | Independent air chamber, send air from two sides | Send air evenly | Improve heat efficiency and prevent partial burning |

7 | Rolling wheel device under chain grate | Change sliding friction to rolling friction | Reduce resistance and improve life of chain grate. |

8 | New type chain plate | With better tensile fatigue strength, more flexibility for coal andbetter burning effect. | Improve reliability |

9 | Single drum water and fire tube drum | Reduce dimension of the boiler, improve water volume in boiler comparingwith other type same capacity boiler | Improve reliability of boiler and flexibility of loading change |