Vertical ZG Series Corner Tube Biomass Boiler

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 Set/Sets per Year |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service, Association, Other |

| Main Products: | Waste Heat Boiler, Carbon Kiln Waste Heat Boiler, Boilers, Glass Kiln Waste Heat Boiler, Boiler |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Fuel: | coal or biomass fuel |

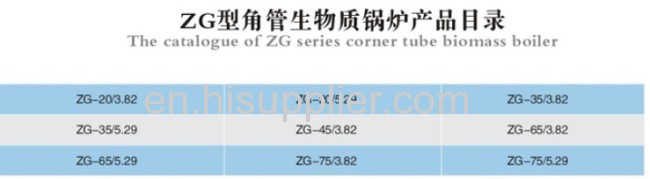

| Output: | steam:rated evaporation:20-75t/h |

| Usage: | Industrial or power station |

| Structure: | water tube |

| Pressure: | medium pressure/high pressure |

| style: | vertical |

| Type: | natural circulation |

| Production Capacity: | 50 Set/Sets per Year |

| Packing: | standard export package |

| Delivery Date: | six months |

Product Description

VerticalZG Series Corner Tube Biomass Boilers

ZG Series Corner Tube Biomass Boiler adopts sectional boiler setting so that the total weight of the boiler is lighter

ZG Series Corner Tube Biomass Boiler adopts sectional boiler setting so that the total weight of the boiler is lighter

We by the abundant technical force, perfect detection means, strict quality management, sophisticated processing equipment, has its place in the same industry. Our company strictly abide by equality and mutual benefit, quality first, customer supreme principle, is willing to provide warm and thoughtful pre-sale service.

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

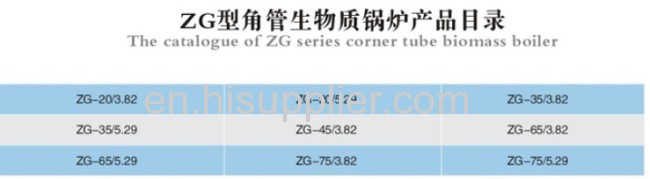

natural circulationZG Series Corner Tube Biomass Boilers:

Output:steam:rated evaporation:20-75t/h

Structure:water tube

style:vertical

ZG Series Corner Tube Biomass Boiler has the following characteristics:

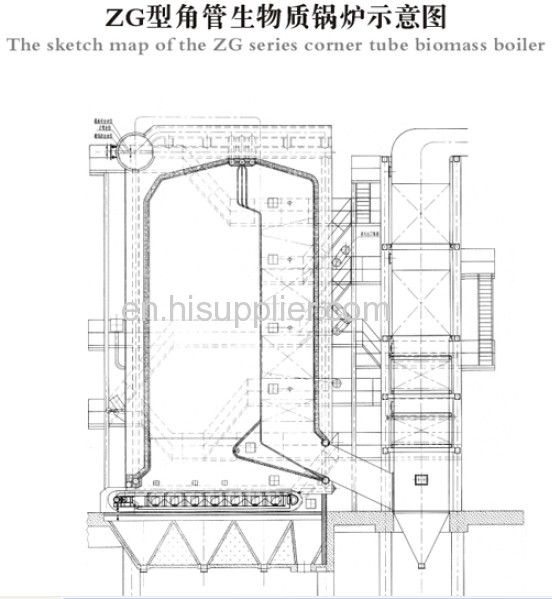

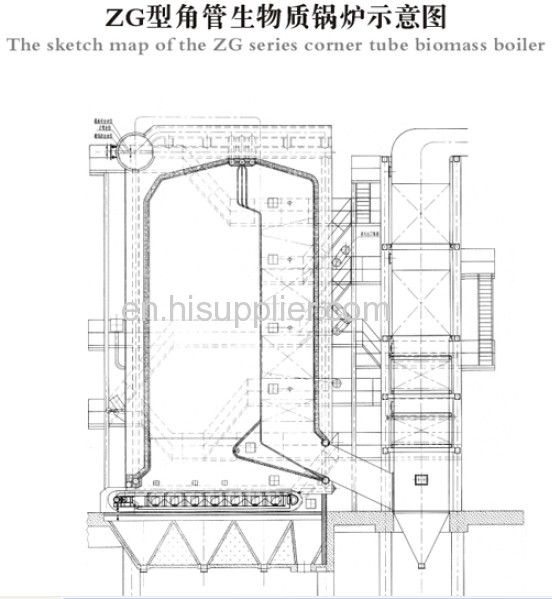

1. ZG Series Corner Tube Biomass Boiler adopts corner tube pattern, self-supporting structure, the problem relating to the expansion and the supporting of the boilers are tackled smartly. The supporting structure is stable and compact.

fruit of co-development of manufacture,university and institution.selfsupporting membrane water cool tubes wall.comprehensive utilization of dust slag

ZG Series Corner Tube Biomass Boiler has the following characteristics:

1. ZG Series Corner Tube Biomass Boiler adopts corner tube pattern, self-supporting structure, the problem relating to the expansion and the supporting of the boilers are tackled smartly. The supporting structure is stable and compact.

2.The furnace and the descending fuel gas duct adopts total welding membrane water cool tubes wall structure, which has the features of good sealing, less heat lost and little pollution.

3. Both the air pre-heater and the economizer adopt case pattern structure, which can ensure them be transported in package, so the installation time can be saved and sealability of the fuel gas duct is strengthened.

4. There is flag pattern heating surface before the high temperature super heater, so the high temperature ability of the super heater can be ensured, meanwhile, the super heater can be operated in the serious fuel gas environment stabely.

5. The crossgrider grate is adopted, so it has the features of less operation resistance, better grate cooling effects, lower breakdown rate, less fuel leak. And the grates are made by the first-class professional manufacture.

6. The fuel is sprayed to the furnace, which can ensure the straticulating combustion and suspending combustion, thus the combustion efficiency is enhanced.

7. ZG Series Corner Tube Biomass Boiler adopts sectional boiler setting so that the total weight of the boiler is lighter.

8. The fuel of ZG Series Corner Tube Biomass Boiler is only or other kinds of biomass material, so the slag of the boiler can be used as fertilizer to agriculture. And it is a high efficiency, energy-saving and environment-friendly product.

Model No.:ZG series Fuel:coal or biomass fuel Usage:Industrial or power station Pressure:medium pressure/high pressure Type:natural circulation Place of Origin:Henan,China (Mainland) Output:steam:rated evaporation:20-75t/h Structure:water tube style:vertical

natural circulationZG Series Corner Tube Biomass Boilers:

Output:steam:rated evaporation:20-75t/h

Structure:water tube

style:vertical

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.

Our corporate culture: outstanding service quality, strict implementation of standards, the system composition, the consummation post-sale service.