SO-120 Pearl Inspect OCT System(NDT photics measure)

| Payment Terms: | Paypal, L/C, T/T, WU |

|---|---|

| Place of Origin: | Guangdong |

Company Profile

| Location: | Guangzhou, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | B Scanner, Ultrasound Diagnose |

Product Detail

| Model No.: | Sonostar SO-120 |

|---|---|

| Brand Name: | sonostar |

| Place of Origin: | Guangdong, China (Mainland) |

Product Description

Specifications

Install and easy to use.

Imaging speed.

Clear and real images, detecting data is very accurate

This product achieves non-destructive testing of pearl bead thickness.

Using low power near-infrared light to achieve the non-destructive imaging of pearl, the optical power illuminated to sample is only 4 ~ 6mW, wavelength is 1.3 microns, non-radioactive, completely non-invasive to the testing workers and pearl samples, radiation shield is not needed to and no potentially harmful X-ray radiation to the staffs; compared to traditional prior transmission X-ray imaging, this product uses an innovative non-contact backscatter imaging technology to achieve a single bead detection, and makes semi-finished pearl and finished jewelry measurements become possible; intuitive pearl beads layer images, accurate measurement of the pearl beads thickness, resolution up to 0.03 mm; instrument miniaturization, installation and use convenient, can be used directly in manufacturing factory, testing organization, distribution units, retail units and other places; fast imaging speed, each sample scan only 0.05 seconds, sorter optional, suitable for pearl farming and grading, screening of production process.

Applied range:

OCT can be applied in quantitative grading of pearl and qualitative assessment of pearl quality. Conclusions are as follows:

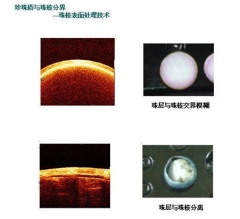

1.Verify the authenticity and varieties of pearls, and distinguish whether pearls is clear;

2.Pearl grating based on nacre thickness measurement , thickness range 0.1~4mm and the error < 10%;

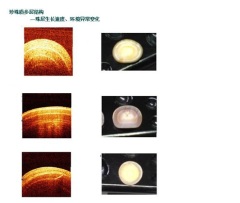

3.According to the pearl internal structure, it can provide supplementary information for pearl cultivation and quality assessment;

4.Without the color and variety restricted;

5.Pearl quality control and identification.

Features

-High sensitivity and resolution: high resolution can achieve 5~15m, clear and real image, detect data is very accurate.

-Fast detection speed: imaging rate reaches20 picture/s, can realize real-time imaging and online detection, scanning speed of frequency-domain scanning system can reach 40000Hz/s, can realize real-time 3d imaging.

-Nondestructive no radiation: no damage to the seized material to complete the detection, and exposure to the seized materials optical power was only 4~6mW, cannot produce any damage and radiation.

-Non-contact: The probe doesnt need to contact with the surface of detection tissue.

Main Technical Parameters:

-Light wavelengths: 1300nm

-Light source power: 12mW

-Sample area light power: 4~6mW

-Vertical resolution: 20m

-Transverse resolution: 20m

-Scanning depth: 5mm(portrait)10mm(landscape orientation)

-Imaging velocity: 20 picture/s

-3D image(optional)

- Ispect depth: 1~4mm(depend on feature of pearl)

-Working distance: 50~70mm

The measuring results of OCT layer quantitative pearl beads is in good agreement with the measurements results of high-resolution micro-scale , compared results including different levels, different colors and different varieties of pearl samples, showing that the technology is applicable to all types of nuclear pearl.

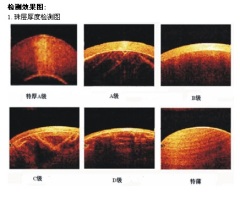

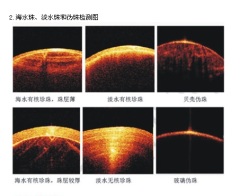

Pearl detection image:

Using the system to detect pearl can realize real-time faultage imaging nondestructively no radioactively, thus analysising, measuring and evaluating the quality of pearl.

Product advantage:

Accurate detection data: intuitive pearl nacre image, accurate measuring nacre thickness of pearl, resolution can reach 0.03mm.

Fast imaging detection speed: each sample use only 1-2 seconds, optional sorting device, suitable for pearl breeding, grading, screening of producing process.

Small portable: instrument miniaturization, easy for installation and using, can be directly used in production factory, testing organization, distribution unit and retail unit, Also applies to flow detection.

In addition, compared to the traditional using X-ray to transmission imaging detection to the pearl, This system uses a innovative contactless backscattering imaging technology to achieve the simple pearl detection, make measuring semi-finished products and finished pearl ornament products comes true. For its no radioactivity, completely no damage to detect workers and pearl sample, the testing laboratory dont need any radioactive shielding, and no potentially X-ray radioactive hazards to workers.

1. Working Sketch of pearl nacre thickness detection

2. Working Sketch of detcetion to Seawater pearl, freshwater pearl and pseudo