Single Bolt Heavy Duty Hose Clamp

| Min. Order: | 500 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 80000 Per Day |

| Place of Origin: | Anhui |

Company Profile

| Location: | Bengbu, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Worm Drive Hose Clamp, Hose Clamp, T Bolt Clamps, Double Wire Clamps, Germany Type Hose Clamp |

Product Detail

| Model No.: | KM5X028 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | K-Seal |

| Material: | all galvanized steel |

| Thickness: | 0.6mm |

| Width: | 18mm |

| Certification: | ISO 9001:2008 |

| Range: | 26-28mm |

| Screw: | M5X40 |

| Load Torque: | 6NM |

| Production Capacity: | 80000 Per Day |

| Packing: | 100/carton |

| Delivery Date: | 25 working day |

Product Description

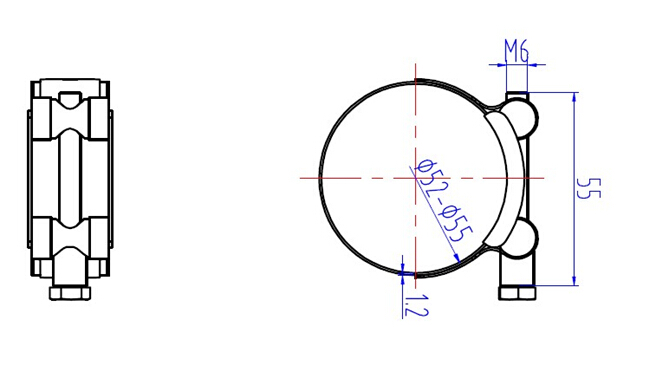

Single Bolt Heavy Duty Hose Clamp

1.Material :all galvanized steel

2.Standard: DIN 3017

3.Feature:(1)Biggeradjusting range (2) Evenly stress when fastening (3) Wrestresistant and high crushing strength

(4) Moderateprice(5) Corrosion resistant , and protects the rubber surface is not damaged (6) Can smoothly , can bereused (7) Ideal fastener of all kinds of gentle andharsh pipes

4. Application: To auto pipe , motor pipe , water pipe , cooling pipe , gas pipeect.

| W1 | W4 | W5 | Diameter (mm) | W1 | W4,W5 | Screw | Load torque |

| Thickness X Width(mm) | Thickness X Width(mm) | ||||||

| KM5X019 | KGM5X019SS | KLM5X019SS | 17-19 | 0.6×18 | 0.6×18 | M5X40 | ≧4.5Nm |

| KM5X022 | KGM5X022SS | KLM5X022SS | 20-22 | 0.6×18 | 0.6×18 | M5X40 | ≧4.5Nm |

| KM5X025 | KGM5X025SS | KLM5X025SS | 23-25 | 0.6×18 | 0.6×18 | M5X40 | ≧4.5Nm |

| KM5X028 | KGM5X028SS | KLM5X028SS | 26-28 | 0.6×18 | 0.6×18 | M5X40 | ≧4.5Nm |

| KM6X031 | KGM6X031SS | KLM6X031SS | 29-31 | 0.8×20 | 0.6×20 | M6X50 | ≧9Nm |

| KM6X035 | KGM6X035SS | KLM6X035SS | 32-35 | 0.8×20 | 0.6×20 | M6X50 | ≧9Nm |

| KM6X039 | KGM6X039SS | KLM6X039SS | 36-39 | 0.8×20 | 0.6×20 | M6X50 | ≧9Nm |

| KM6X043 | KGM6X043SS | KLM6X043SS | 40-43 | 0.8×20 | 0.6×20 | M6X50 | ≧9Nm |

| KM6X047 | KGM6X047SS | KLM6X047SS | 44-47 | 1.2×22 | 0.8×22 | M6X55 | ≧9Nm |

| KM6X051 | KGM6X051SS | KLM6X051SS | 48-51 | 1.2×22 | 0.8×22 | M6X55 | ≧9Nm |

| KM6X055 | KGM6X055SS | KLM6X055SS | 52-55 | 1.2×22 | 0.8×22 | M6X55 | ≧9Nm |

| KM6X059 | KGM6X059SS | KLM6X059SS | 56-59 | 1.2×22 | 0.8×22 | M6X55 | ≧9Nm |

| KM6X063 | KGM6X063SS | KLM6X063SS | 60-63 | 1.2×22 | 0.8×22 | M6X55 | ≧9Nm |

| KM6X067 | KGM6X067SS | KLM6X067SS | 64-67 | 1.2×22 | 0.8×22 | M6X55 | ≧18Nm |

| KM8X073 | KGM8X073SS | KLM8X073SS | 68-73 | 1.5×24 | 0.8×24 | M8X70 | ≧18Nm |

| KM8X079 | KGM8X079SS | KLM8X079SS | 74-79 | 1.5×24 | 0.8×24 | M8X70 | ≧18Nm |

| KM8X085 | KGM8X085SS | KLM8X085SS | 80-85 | 1.5×24 | 0.8×24 | M8X70 | ≧18Nm |

| KM8X091 | KGM8X091SS | KLM8X091SS | 86-91 | 1.5×24 | 0.8×24 | M8X70 | ≧18Nm |

| KM8X097 | KGM8X097SS | KLM8X097SS | 92-97 | 1.5×24 | 0.8×24 | M8X70 | ≧18Nm |

| KM8X103 | KGM8X103SS | KLM8X103SS | 98-103 | 1.5×24 | 0.8×24 | M8X70 | ≧18Nm |

| KM8X112 | KGM8X112SS | KLM8X112SS | 104-112 | 1.5×24 | 0.8×24 | M8X80 | ≧18Nm |

| KM8X121 | KGM8X121SS | KLM8X121SS | 113-121 | 1.5×24 | 0.8×24 | M8X80 | ≧18Nm |

| KM8X130 | KGM8X130SS | KLM8X130SS | 122-130 | 1.5×24 | 0.8×24 | M8X80 | ≧18Nm |

| KM10X139 | KGM10X139SS | KLM10X139SS | 131-139 | 1.7×26 | 1.0×26 | M10X90 | ≧29Nm |

| KM10X148 | KGM10X148SS | KLM10X148SS | 140-148 | 1.7×26 | 1.0×26 | M10X90 | ≧29Nm |

| KM10X161 | KGM10X161SS | KLM10X161SS | 149-161 | 1.7×26 | 1.0×26 | M10x110 | ≧29Nm |

| KM10X174 | KGM10X174SS | KLM10X174SS | 162-174 | 1.7×26 | 1.0×26 | M10x110 | ≧29Nm |

| KM10X187 | KGM10X187SS | KLM10X187SS | 175-187 | 1.7×26 | 1.0×26 | M10x110 | ≧29Nm |

| KM10X200 | KGM10X200SS | KLM10X200SS | 188-200 | 1.7×26 | 1.0×26 | M10x110 | ≧29Nm |

| KM10X213 | KGM10X213SS | KLM10X213SS | 201-213 | 1.7×26 | 1.0×26 | M10x110 | ≧29Nm |

| KM10X226 | KGM10X226SS | KLM10X226SS | 214-226 | 1.7×26 | 1.0×26 | M10x110 | ≧29Nm |

| KM10X239 | KGM10X239SS | KLM10X239SS | 227-239 | 1.7×26 | 1.0×26 | M10x110 | ≧29Nm |

| KM10X252 | KGM10X252SS | KLM10X252SS | 240-252 | 1.7×26 | 1.0×26 | M10x110 | ≧29Nm |

Q And A:

1. Q: Does your hose clamps produce by your own company or import?

A: The clamps is home made by our own factory. King Seal is an American-owned manufacturer in China. The Equipment and Technology are from USA.

2. Q: Which is better material for SS200 and SS300? We need the best one.

A: Regarding corrosion resistance, SS 300 is better than SS200, The other performances are basically same. If you prefer better corrosion resistance, SS316 is the best choice.

3. Q: We do biotechnology business. The hose clamps application environment involves acid-base environment. Please advise whether we can use SS304?

A: SS304 has relatively high corrosion resistance, but if Acid-base environment is strongly high, SS316 clamp is the best choice.

4. Q: Is SS304 material magnetic?

A: SS304 itself has no magnetism, But it could generate certain magnetism during production process.

5. Q: Your stainless steel clamps looks good, do you electroplate them on the surface?

A: We run some polish process on the surface but it's not electroplated.