310s.s Hexsteel for lining fixing

20.0~30.0 USD

| Min. Order: | 100 Kilometer |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 pcs/week |

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Model No.: | FR-01 |

|---|---|

| Means of Transport: | Ocean |

| Type: | Steel Plate |

| Surface Treatment: | Others |

| Technique: | Hot Rolled |

| Brand Name: | 369 |

| Steel Grade: | stainless steel |

| Thickness: | 1.0-2.5mm |

| Production Capacity: | 100 pcs/week |

| Packing: | pallet |

| Delivery Date: | 15 days |

Product Description

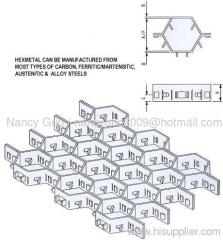

Materials: A3 0Cr13 0Cr18Ni9 1Cr18Ni9Ti 310S Cr25Ni20 304 310

THE thickness: according to the client

the height:10-50mm

the diameter:30-100mm

THE thickness: according to the client

the height:10-50mm

the diameter:30-100mm

hexmesh is mainly used to fasten the refractory ducts linings, etc. Catalytic cracker, reactors, cyclone and u-type actifier ducts in oil and chemical industry; Furnaces linings erosion resistant, ducts elbow in electrical industry; Furnaces, actifier reactors in petroleum refinery. Alloys(1Cr13) mainly for refractory resistant, 1Cr18Ni9Ti or 0Cr18Ni9 for erosion resistant.

Since Hex Metal's flexibility allows it to be rolled, it easily conforms to circular shapes. It is ideal for lining Ducts, Furnaces, Reactor Vessels, Cyclones, Flue Gas Lines and other high temperature equipment of virtually any shapes.

Flex metal is the direct counterpart of Hex metal. It performs all the same functions in reinforcement of thin wall refractory linings, while its' design allows free form rolling to very small diameters. Hex metal becomes impractical when the section of plant being protected is of small diameter. The free rolling capabilities of Flex metal allows plant as small as 150 mm to be lined. Typical applications include Air Distributors, Cyclone Diplegs, Fan Cases, or any other plants where the practicality of free rolling material is beneficial to maintenance activities.