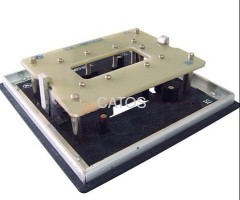

Wave Soldering Pallets with Cover Plate

| Payment Terms: | T/T, WU |

|---|---|

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

| Main Products: | Hold Downs And Clamps, Wave Soldered Pallets Electronic Assembly, PCB Wave Soldering Pallet And Carriers, Durstone Wave Sodering Stencil, Durostone Solder Pallet Materials |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Brand Name: | CATOS |

| Color: | Black |

| Thickness: | common 3,4,5,6,8,10mm,others can be made specially |

| Dimension: | 1020mm x1220mm |

| Application: | Selective wave soldering pallets |

| Temperature: | 280(385 max)℃ |

| Packing: | PE package film ,cartons |

| Delivery Date: | 7~30 working days |

Product Description

Detailed Product Description

CATOS Brand complete range of wave solder pallets, fixtures and tooling will stand up to your lead free requirements and optimize your wave solder process, assisting you in maximizing your yields and improving your overall process reliability.

Selective wave solder pallets

Wave solder pallets are the fastest and most cost-effective method of soldering through-hole components post-reflow.

Pallets permit wave solder processing of through-hole components while masking solder-side SMT components and critical board features from molten solder.

Advantages

- Wave Solder Pallets provide strong, stable support for PCB throughout the wave solder process

- Wave Solder Pallets permit wave solder processing of through-hole components when masking solder-side SMT components and critical board features from molten solder

- Wave Solder Pallets provide thermal protection for printed circuit board areas which are heat sensitive

- Wave Solder Pallets prevent topside component movement throughout wave solder

- Wave Solder Pallets align and position topside components throughout wave solder

- Wave Solder Pallets increase assembly production efficiently by eliminating hand gluing and masking operations

- Wave Solder Pallets ensure higher quality, repeatable process results in the assembly lines

- Wave Solder Pallets abate bridging and skipping soldering defects

- Wave Solder Pallets provide safe, easy, ergonomic handling of PCB