Stone Production Line

999.0~99999.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | T/T L/C |

| Supply Ability: | 50 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Vibrating Feeder Series, Vibrating Screen, Yuda Stone Production Line, Rock Jaw Crusher, Sand Making Machine In China |

Product Detail

| Means of Transport: | According to customer's requirments |

|---|---|

| Application: | Others |

| Type: | Crusher |

| Brand Name: | Yuda |

| Production Capacity: | 50 sets per month |

| Packing: | Standard Export Packaging |

| Delivery Date: | 15 days |

Product Description

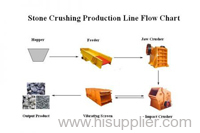

Stone Production Line

Stone production line includes vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor and centrally electric controlling system, etc. The designed capacity is from 50t/h to 500t/h. To meet customers specific requirement, we can also add other equipments such as cone crusher, dust catcher on the production line.

Jaw Crusher

Our jaw crusher is a high efficient and energy saving machinery which introduces successful experience of the same machines home and abroad. These series of jaw crushers are widely used in mine, metallurgy, construction, road building, railway, water conservancy and chemical industry. They feature high crushing ratio, good shape in product, simple structure, reliable performance and low operation cost. They are ideal choice for primary crushing.

Working principle of jaw crusher:

The motor drives the belt and the grooved wheel, which connect the eccentric shaft. Through the movement of eccentric shaft, the movable jaw plate moves up and down. When movable jaw plate moves up, the angle between it and toggle plate will be enlarged, so the movable jaw plate will be close to fixed jaw plate. Then, the materials will be pressed and crushed; when movable jaw plate moves down, the angle between it and toggle plate will be reduced, movable jaw plate will moves away from fixed jaw plate due to the tension rod and springs. At this moment, the crushed materials will be discharged at discharge opening. With moving of motor and periodical movement of movable jaw plate, material will be crushed and discharged gradually, so that batch production will be reached.

Impact crusher

Impact crusher is a newly developed crusher based on advanced technologies home and abroad as well as Chinas practical mining conditions. It is widely applied in various material crushing, railway, energy, cement, chemical industry and construction. The final size can be adjusted and crushing style is versatile the final product takes on cubic shape with no tension and cracks; high chrome blow bar, impact and erasion-resistant, no-key connection, high impact strength; it processes the advantages of easy maintenance, high reliability; complete crushing ability, high productivity, little erasion in spare parts, and high comprehensive efficiency.

Working principle of impact crusher:

During the operation, with the drive of motor, the rotors turn at a high speed. When materials enter the blow bar area, they are thrown to the impact plate above the rotors with the strike strength of blow bar. Then the materials are rebounded back to the blow bar for recrushing. In this way, the materials will be crushed many times in the crusher until they can meet standard and be discharged at the bottom of the machine. The size and shape of final products can be adjusted by changing the gap between the impact rack and the rotors.

Process of stone production line:

Big materials are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushing. After first crush, the material will transferred to impact crusher by belt conveyor for secondary crush; the crushed materials will then transferred to vibrating screen for separating. After separating, the parts that can meet standard will be transferred away as final products, while the other parts will be returned to impact crusher, thus forming a closed circuit. Size of final products can be combined and graded according to customers specific requirement. We can also equip dust catcher system to protect environment, any changes are subject to the products