Hastelloy X Mesh Screen

| Min. Order: | 30 Square Meter |

|---|---|

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 10,000 squarevmeters/month |

| Place of Origin: | Hebei |

Company Profile

| Location: | Beijing, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Nickel Wire Mesh, Monel 400 Wire Mesh Demister, Incoloy Sheet Plate Strip, Monel Sheet Plate Strip, Inconel 625 Alloy Strip Sheet Plate |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Application: | Others |

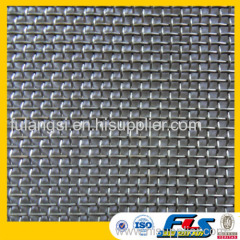

| Type: | Woven |

| Material: | Others |

| Brand Name: | XinXing |

| Mesh Size: | 0.5-250 mesh |

| Hastelloy X Mesh Screen: | Hastelloy X Wire Mesh |

| Production Capacity: | 10,000 squarevmeters/month |

| Packing: | Standard package |

| Delivery Date: | 2 to 30 days |

Product Description

Hastelloy X Mesh/Screen is a nickel-chromium-iron-molybdenum superalloy with outstanding high temperature strength, oxidation resistance, and fabricability. Hastelloy X Mesh/Screen's oxidation resistance is excellent up to 2200° F. Hastelloy X Mesh/Screen has also been found to be exceptionally resistant to stress-corrosion cracking in petrochemical applications. Matrix stiffening provided by the molybdenum content results in high strength in a solid-solution alloy having good fabrication characteristics. Although it is primarily noted for heat and oxidation resistance, Hastelloy X Meshalso has good resistance to chloride stress-corrosion cracking, carburization, and excellent resistance to reducing or carburizing atmospheres.

Characteristics of Hastelloy X Mesh/Screen

Outstanding oxidation resistance through 2000° FCharacteristics of Hastelloy X Mesh/Screen

Resistant to carburization and nitriding

Excellent high temperature strength

Good resistance to chloride stress-corrosion cracking

Hastelloy X Mesh/Screen Applications

Gas turbines

Petrochemical industry

Industrial furnaces

Heat treating equipment

Nuclear engineering

Jet engine combustion chambers

Aircraft cabin heaters

Turbine exhaust components

Hastelloy X Mesh/Screen is one of the most widely used nickel base superalloys for gas turbine engine combustion zone components such as transition ducts, combustor cans, spray bars and flame holders as well as in afterburners, tailpipes and cabin heaters. It is recommended for use in industrial furnace applications because it has unusual resistance to oxidizing, reducing and neutral atmospheres. Hastelloy X is also used in the chemical process industry for retorts, muffles, catalysts support grids, furnace baffles, tubing for pyrolysis operations and flash drier components.

Fabrication with Hastelloy X Mesh/Screen

Chemical Composition of Hastelloy X

Element | Min | Max |

Molybdenum | 8.00 | 10.0 |

Chromium | 20.5 | 23.0 |

Iron | 17.0 | 20.0 |

Tungsten | 0.20 | 1.00 |

Cobalt | 0.50 | 2.50 |

0.05 | 0.015 | |

Silicon | -- | 1.00 |

Manganese | -- | 1.00 |

Boron | -- | 0.01 |

Phosphorus | -- | 0.04 |

Sulfur | -- | 0.03 |

Nickel | Remainder | |

Physical Properties of Hastelloy X

Physical Properties | °F | British Units | °C | Metric Units |

Density | 72 | 0.297 lb./cubic in. | 22 | 8.22 g/cubic cm. |

Melting Range | 2300- 2470 | 1260- 1355 | ||

Electrical Resistivity | 72 | 46.6 microhm-in. | 22 | 1.18 microhm-m |

Mean Coefficient of Thermal Expansion | 79-200 | 7.7 microin./in.-°F | 26-100 | 13.8 X 10(-6)m/m-K |

79-1000 | 8.4 microin./in.-°F | 26-500 | 14.9 X 10(-6)m/m-K | |

79-1200 | 8.6 microin./in.-°F | 26-600 | 15.3 X 10(-6)m/m-K | |

79-1350 | 8.8 microin./in.-°F | 26-700 | 15.7 X 10(-6)m/m-K | |

79-1500 | 8.9 microin./in.-°F | 26-800 | 16.0 X 10(-6)m/m-K | |

76-1650 | 9.1 microin./in.-°F | 26-900 | 16.3 X 10(-6)m/m-K | |

79-1800 | 9.2 microin./in.-°F | 26-1000 | 16.6 X 10(-6)m/m-K | |

Thermal Conductivity | 70 | 63 Btu-in/ft²-hr-°F | 20 | 9.7* W/m-K |

200 | 76 Btu-in/ft²-hr-°F | 100 | 11.1 W/m-K | |

500 | 98 Btu-in/ft²-hr-°F | 300 | 14.7 W/m-K | |

1100 | 144 Btu-in/ft²-hr-°F | 600 | 20.6 W/m-K | |

1300 | 159 Btu-in/ft²-hr-°F | 700 | 22.8 W/m-K | |

1500 | 174 Btu-in/ft²-hr-°F | 800 | 25.0 W/m-K | |

1700 | 189 Btu-in/ft²-hr-°F | 900 | 27.4* W/m-K | |

Poisson's Ratio | -78 22 | 0.328 0.320 | -108 72 | 0.328 0.320 |

Magnetic Permeability | Room | <1.002 at 200 oersteds (15,900 A/m) | ||

Mesh Weaving Method

Perforated Mesh |

Dutch Twill Weave Cloth |

Dutch Plain Weave |

Reverse Dutch Weave Cloth |

5-heddle Weave Mesh |

Cross twill weave |