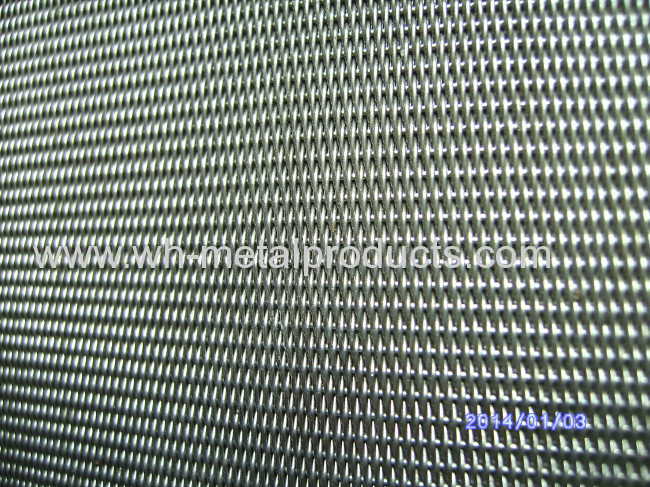

plain dutch weave wirecloth,twill dutch weave wire cloth

| Min. Order: | 30 Square Meter |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, T/T, WU |

| Supply Ability: | 500 square meter |

| Place of Origin: | Hebei |

Company Profile

| Location: | Hengshui, Hebei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | WHMP-PDW01 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Filter |

| Type: | Woven |

| Brand Name: | wanhai |

| Mesh Size: | 12/64,14/88,24/110,30/150,18/100,55/280 |

| Applications:: | used for absorption, evaporation and filtration process in petroleum, chemical, medicine, metallurgy, machinery, ship |

| material: | stainless steel ansi304, ansi316,Plain steel wire,brass wire,copper and bronze, aluminum alloy, nickel alloy |

| wire mesh Extruder screens: | serves for metallurgy, coal, rubber, petroleum, chemical, pharmaceutical, automotive, ceramics, glass and other industri |

| wire mesh extruder screen filters discs:: | single and multiple layers with & without frame, multiple layers with spot welding. |

| wire cloth is available in:: | stainless steel, phosphor-bronze,monel, nickel,steel,copper,brass |

| Extruder screens weave ways: | plain weave,dutch weave,twill weave,herringbone weave,reverse dutch weave |

| market: | china, europe, america |

| standards: | compliance with ISO 9001:2008 and ASTM standards. |

| wire mesh factory origin: | anping,china |

| Production Capacity: | 500 square meter |

| Packing: | pvc shrink,then carton box,then wooden case |

| Delivery Date: | 15days |

Product Description

Dutch weave wire cloth,Dutch weave filter mesh provides superior filtration capabilities for a wide range of applications, including pressure, fuel and liquid filters for the aerospace, petrochemical, pharmaceutical, mining and waste water treatment industries.

Dutch weave include: plain dutch weave,twill dutch weave, reverse dutch weave.

wire material: stainless steel ansi304, ansi316,Plain steel wire,brass wire,copper and bronze, aluminum alloy, nickel alloy,Copper-Clad Steel Wire.

Plain Dutch weave wire cloth is woven using two sizes of wire. Smaller wires, as small as micron size, are used in the shute direction and are woven with a larger warp wire. The smaller wires are woven tightly together, providing a tight mesh for filtering. The larger wire provides strength to the mesh. The primary uses of this wire cloth are filtration and separation of liquid and slurry products.

Twill Dutch weave wire cloth combines Dutch and twill weaving to provide a fine mesh filtering cloth. Shute wires are passed over and under two warp wires, providing a tight, fine filter with tapered openings. The weaving process allows for the use of very fine wires, to micron size, producing filtering mesh for gas and liquid applications.

Plain Dutch Weave & Twill Dutch Weave Wire Cloth Specifications

The table below shows the standard specifications for Plain Dutch Weave(PDW) wire cloth and Twill Dutch weave(TDW) wire cloth.

Weave Type | Mesh Count | Warp Wire | Shute Wire | Absolute | Nominal | Weight |

PDW | 8x20 | 0.014 | 0.0126 | 330-350 | 280 | 49 |

PDW | 12x64 | 0.024 | 0.0165 | 270-290 | 200 | 84 |

PDW | 14x88 | 0.02 | 0.013 | 220-240 | 150 | 75 |

PDW | 16x80 | 0.0169 | 0.0134 | 225-235 | 140 | 79 |

PDW | 24x110 | 0.015 | 0.01 | 115-125 | 80 | 55 |

PDW - Twin Warp | 24x128 | 2 x .010 | 0.004 | 110-120 | 75 | 34 |

PDW | 30x150 | 0.009 | 0.007 | 110-112 | 63 | 33 |

PDW - Twin Warp | 30x150 | 2 x .009 | .007" | 95-113 | 60 | 33 |

PDW | 40x200 | 0.007 | 0.0055 | 70-75 | 55 | 27 |

PDW | 50x250 | 0.0055 | 0.0045 | 58-63 | 40 | 22 |

PDW | 80x400 | 0.005 | 0.003 | 40-45 | 35 | 17 |

TDW | 30x250 | 0.01 | 0.008 | 110-120 | 53 | 66 |

TDW | 80x700 | 0.004 | 0.003 | 35-40 | 25 | 25 |

TDW | 120x400 | 0.004 | 0.0025 | 50-55 | 40 | 15 |

TDW | 165x800 | 0.0028 | 0.002 | 25-28 | 15 | 14 |

TDW | 200x600 | 0.0024 | 0.0018 | 30 | 20 | 10 |

TDW | 165x1400 | 0.0028 | 0.0016 | 16-20 | 10 | 14 |

TDW | 200x1400 | 0.0028 | 0.0016 | 12-14 | 5 | 15 |

TDW | 325x2300 | 0.0014 | 0.001 | 8-9 | 2 | 10 |

TDW | 400x2800 | 0.001 | 0.0008 | 6-7 | 1 | 8 |

Reverse Dutch weave wire cloth are used for high pressure filtration applications. This type of pattern is used in the food and beverage industry, plastics, aerospace, petrochemical and chemical applications. We can provide reverse Dutch weave belts with high tensile warp wires for a wide range of screen changers.