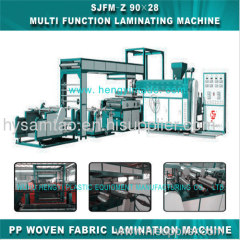

PP WOVEN BAG LAMINTING MACHINE

30000.0~35000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5 sets per month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Wuhu, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Woven Bag Printing Machine, SHUTTLE LOOM, PP Woven Bag Printing Machine, PP WOVEN BAG MAKING MACHINE |

Product Detail

| Model No.: | SJFM-Z 90X28 |

|---|---|

| Means of Transport: | Ocean |

| Plastic Type: | PP/PE |

| Use: | Others |

| Shaft Design: | Double |

| Brand Name: | HENGYI |

| Power: | 49.5KW |

| DIAMTER OF EXTRUDER SCREW: | 90MM |

| L/D RATIO OF SCREW: | 28:1 |

| QUANTITY OF DIE: | 2 PCS |

| WIDTH OF DIE: | 1000MM |

| TOTAL POWER: | 49.50 |

| POWER OF EXTRUDER ENGINE: | 15KW |

| HEATING POWER OF EXTRUDER: | 29KW |

| POWER OF DRAWING ENGINE: | 5.5KW |

| WIDTH OF LAMINATING(MAX): | 750MM |

| SPEED OF LAMINATING: | 30~100 M/ MIN |

| Production Capacity: | 5 sets per month |

| Packing: | WOODEN PALLET |

| Delivery Date: | 35 DAYS AFTER DEPOSIT |

Product Description

This machine adopts double die heads plastic extruding parts, it could coats the rolled plastic woven sacks with single or double sides films, laminates the sacks with the single or double sides papers, also could laminates the sacks with single or double sides OPP, CPP films.

As the production flow, rolled plastic woven sacks is sending from the emptying and correction device, the paper, OPP or CPP color films is sending from the double position empty devices, through the four pressure rollers, laminating parts, then get to the edge cutting and winding device. The whole production flow was equipped with the advanced electricity, tension control system and mechanical device, it has realized to do single regulator and group control at the same time, also it could laminate the sacks with single or double sides OPP, CPP color films. Due to follow the computer magnetic optical electricity eye-tracking regulator, the automation of this machine has greatly improved. The extruding machine takes the automatic temperature control, auto material feeding device and frequency speed regulator.

This machine unit has merits as the advanced technology, easy operation, high productivity, low cost, evident economic benefits and so on.

As the production flow, rolled plastic woven sacks is sending from the emptying and correction device, the paper, OPP or CPP color films is sending from the double position empty devices, through the four pressure rollers, laminating parts, then get to the edge cutting and winding device. The whole production flow was equipped with the advanced electricity, tension control system and mechanical device, it has realized to do single regulator and group control at the same time, also it could laminate the sacks with single or double sides OPP, CPP color films. Due to follow the computer magnetic optical electricity eye-tracking regulator, the automation of this machine has greatly improved. The extruding machine takes the automatic temperature control, auto material feeding device and frequency speed regulator.

This machine unit has merits as the advanced technology, easy operation, high productivity, low cost, evident economic benefits and so on.