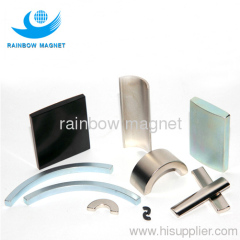

Black smooth arc NdFeB magnets

| Min. Order: | 5000 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 2000tons per year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Origin: | China |

| Brandname: | sunrise |

| Maximum operating temperature: | +60/+80 deg C to +220/+230 deg C |

| Certificate: | ISO9001 |

| Size: | ODXIDXthickness, Customized |

| Coating: | Ni, Zn, Epoxy, Ag, Parylene, etc |

| Parameters: | Grade,Size,Coating,Magnetization Direction,Quantity,etc |

| Composition: | rare earth material |

| Production Capacity: | 2000tons per year |

| Packing: | standard exporting packing |

| Delivery Date: | 25 days after receiving depoist |

Product Description

Product Name:Black smooth arc NdFeB magnets

All the Neodymium Iron Boron, NdFeB, magnets are prone to corrosion (a method similar to rusting). All Neodymium Iron Boron, NdFeB, magnets will require a form of protective coating. The standard coating is a triple layer plating of Nickel-Copper-Nickel (Ni-Cu-Ni). Unless requested otherwise, this Ni-Cu-Ni coating is always applied to the magnets. It should be noted that the level of protection given by any coating depends on the environment the magnet will be subjected to and how the coating is looked after.

The magnetic output from the "Neo" magnet varies with temperature. The output falls with increasing temperature but usually returns as it cools (the degree of fall with rising temperature is dependent on the reversible temperature coefficients). It is possible to permanently reduce the magnetic output through too high a temperature (a permanent demagnetisation).

The level of permanent demagnetisation depends on the magnet shape, the total magnetic circuit and the actual shape of the BH curve (which will vary depending on the grade of "Neo" chosen). Neodymium Iron Boron, NdFeB, magnets are also affected by external demagnetisation fields and by radiation, both of which can demagnetise the magnet, the latter permanently demagnetising.

All the Neodymium Iron Boron, NdFeB, magnets are prone to corrosion (a method similar to rusting). All Neodymium Iron Boron, NdFeB, magnets will require a form of protective coating. The standard coating is a triple layer plating of Nickel-Copper-Nickel (Ni-Cu-Ni). Unless requested otherwise, this Ni-Cu-Ni coating is always applied to the magnets. It should be noted that the level of protection given by any coating depends on the environment the magnet will be subjected to and how the coating is looked after.

The magnetic output from the "Neo" magnet varies with temperature. The output falls with increasing temperature but usually returns as it cools (the degree of fall with rising temperature is dependent on the reversible temperature coefficients). It is possible to permanently reduce the magnetic output through too high a temperature (a permanent demagnetisation).

The level of permanent demagnetisation depends on the magnet shape, the total magnetic circuit and the actual shape of the BH curve (which will vary depending on the grade of "Neo" chosen). Neodymium Iron Boron, NdFeB, magnets are also affected by external demagnetisation fields and by radiation, both of which can demagnetise the magnet, the latter permanently demagnetising.