Edge polish Arc NdFeB magnets

| Min. Order: | 5000 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 2000tons per year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Origin: | China |

| Brandname: | sunrise |

| Maximum operating temperature: | +60/+80 deg C to +220/+230 deg C |

| Certificate: | ISO9001 |

| Size: | ODXIDXthickness, Customized |

| Coating: | Ni, Zn, Epoxy, Ag, Parylene, etc |

| Parameters: | Grade,Size,Coating,Magnetization Direction,Quantity,etc |

| Composition: | rare earth material |

| Production Capacity: | 2000tons per year |

| Packing: | standard exporting packing |

| Delivery Date: | 25 days after receiving depoist |

Product Description

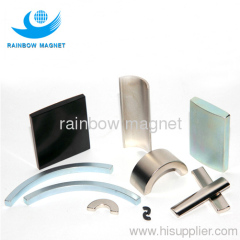

Product Name:Edge polish Arc NdFeB magnets

Apart from offering over 1100 combinations of NdFeB grade and finish, we also manufacture bespoke NdFeB sizes upon request. The NdFeB magnets vary from D1mm x 1mmA discs up to e.g. 200mm x 130mm x 25mmA blocks. Standard NdFeB tolerances are +/-0.1mm. +/-0.05mm tolerances are also available for these Neodymium Iron Boron magnets. We can produce smaller Neodymium magnets down to +/-0.005mm tolerances as part of our bespoke Precision NdFeB range (we would specify the tolerance that could be achieved for each shape but please note that the production runs would be subject to 100k minimum order quantity).

Apart from offering over 1100 combinations of NdFeB grade and finish, we also manufacture bespoke NdFeB sizes upon request. The NdFeB magnets vary from D1mm x 1mmA discs up to e.g. 200mm x 130mm x 25mmA blocks. Standard NdFeB tolerances are +/-0.1mm. +/-0.05mm tolerances are also available for these Neodymium Iron Boron magnets. We can produce smaller Neodymium magnets down to +/-0.005mm tolerances as part of our bespoke Precision NdFeB range (we would specify the tolerance that could be achieved for each shape but please note that the production runs would be subject to 100k minimum order quantity).

The NdFeB (NIB) magnets, in disc, ring and rod forms, are usually axially magnetised (the round ends are the magnet poles). Diametrically magnetised discs and rings can be produced upon request (looking at the circular end face, the magnetism runs from the 12 o'clock position to the 6 o'clock position in diametrically magnetised magnets). Likewise, the rectangular blocks can be specially produced to be magnetised in any of the three axes (the magnets cannot be re-magnetised in another axis due to the method of production – the sintered NdFeB is anisotropic). Arcs, trapezoids and other shapes and assemblies (e.g. Pot Magnets, Separator Grids, etc) can generally also be produced. Bespoke Directions of Magnetisation within the magnet shape may also be possible (subject to confirmation) e.g. for Halbach Array assemblies.