Corrguated Paper Box with window

0.1~0.2 USD

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000000pcs per month |

| Place of Origin: | Zhejiang |

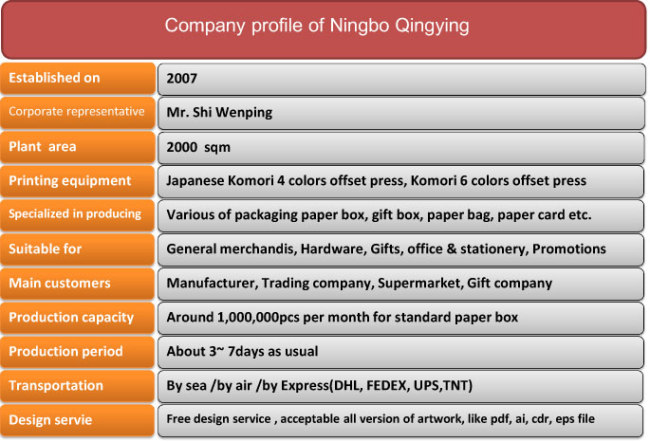

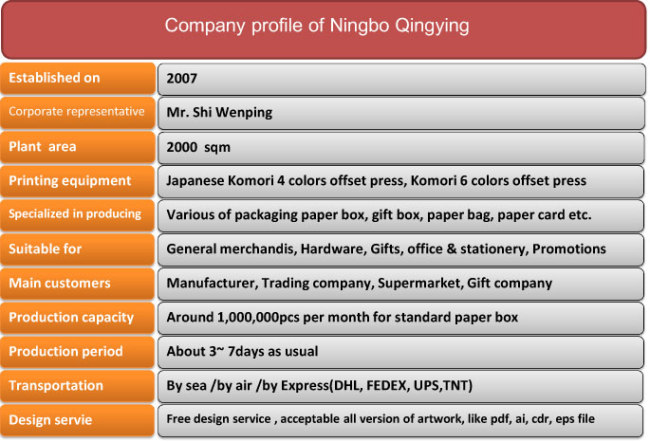

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

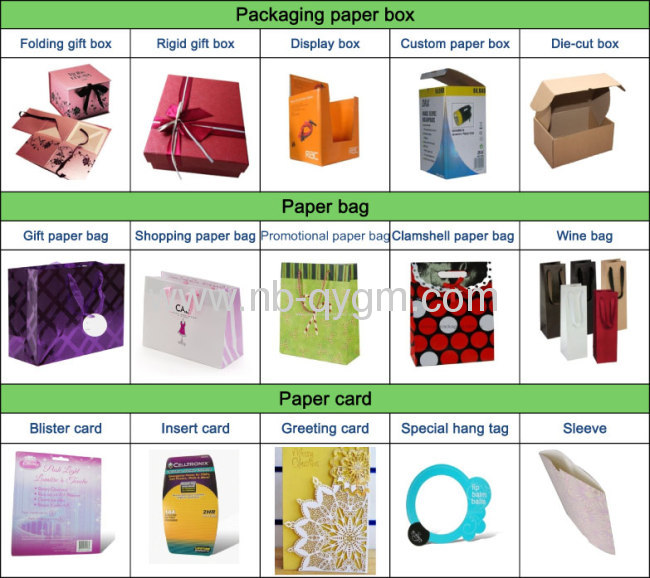

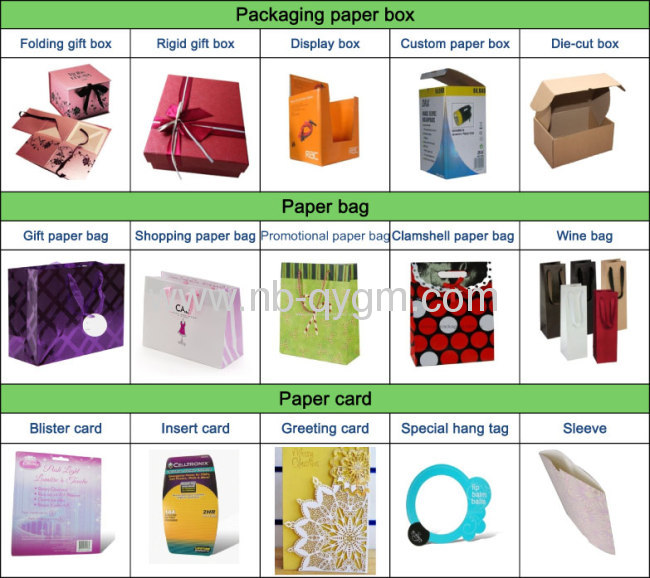

| Main Products: | Paper Gift Packaging Boxes, Greeting Cards, Promotional Paper Handbag, Folding Packaging Box, Die-cut Shipping Boxes |

Product Detail

| Model No.: | ARB13102 |

|---|---|

| Means of Transport: | Ocean, Air |

| Shape: | With Window |

| Feature: | Recycled Materials |

| Material: | Corrugated Paper |

| Usage: | Electronics |

| Brand Name: | QY |

| Description:: | Corrguated Paper Box with window |

| Size:: | 80 x 25 x 250 mm |

| Material: | Corrguated paper |

| Application: | Packaging boxes for Electronics |

| Printing:: | CMYK printing |

| Surface treatment:: | Matte Lamination |

| Box style:: | Stainght tuck paper boxes with hang tag |

| Feature:: | Folding paper boxes with window |

| OEM service: | YES |

| M.O.Q.:: | 1000pcs |

| Production Capacity: | 1000000pcs per month |

| Packing: | standard exporting cartons |

| Delivery Date: | 20~30days |

Product Description

Product name:Corrguated Paper Box with window

The main paperboard material and technical information which is also suitable forCorrguated Paper Box with window , please check the below tables:

Please kindly contact us for more details.

Printing colors: CMYK

Glossy lamination

Ship or storage by flap, it is easy to shape when you pack the flashlight

Recyclable raw material

The main paperboard material and technical information which is also suitable forCorrguated Paper Box with window , please check the below tables:

| LAMINATION | The printed sheet is coated with a protective layer of plastic or metal foil - the laminate. Usually there are three types of lamintation, they are gloss, matt and dull polish laminates, gloss and matt are all popular. The laminate provides excellent protection against dirt, moisture and wear. Lamination can also be done for aesthetic reasons. |  |

| VARNISHING | To add a thin water glazing oil on the surface, in order to improve printing surface. | |

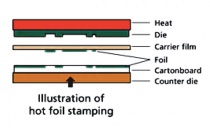

| HOT FOIL STAMPING | A text or pattern in metallic foil is applied to the cartonboard with the aid of heat, often in combination with embossing |  |

| EMBOSSING | The raising of paper using specific tools to accomplish the task, the part of embossing looks outstanding and a little higher than circumjacent paper. |  |

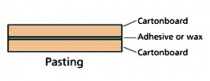

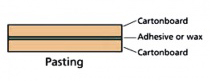

| PASTING | To combine two or more cartonboard sheets together with adhesive or wax to create a single unit. |  |

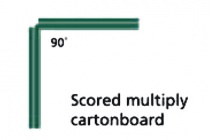

| SCORING | A fine line is scored in the cartonboard to create a flexible hinge. A scored line is less durable than a crease line. |  |

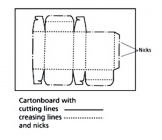

| DIE CUTTING | Die cutting - it is necessary to cut into a shape, e.g. to create a blank which can be folded and erected to form a carton. After printing, die-cutting and creasing are done simultaneously in die-cutting machines. Before procedure of Die cutting, it is important to make a precision cutting mould in advance. |  |

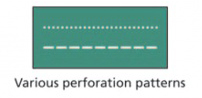

| PERFORATION | A row of punched holes which make it easier to tear off e.g. a coupon or reply card. |  |

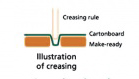

| CREASING | Creasing is important and necessary for folding box, it is different with scoring, it is pressed by certain power through creasing machine, there is no break on the surface. When you fold the box, it is easy to shape as creasing line. |  |

| Type of paperboard | SBS (Solid Bleach Sulplate)orSBB (Solid Bleach Board) |

| Description | also refers to: Coated Ivory Board, White Card paper)1. SBB or SBS consist of bleached chemical pulp inside and coating outside, it is a virgin fibre grade of paperboard 2. The color: white on two side. A good whiteness with three grades: grade A not less than 92%, grade B not less than 87% and Grade C not less thana 82%. 3. A medium density board with good printing properties.4. Easy to be cut, creased, hot foil stamped and embossed. |

| Type of paperboard | SUB (Solid unbleached board) |

| Description | SUB (Solid Unbleached Board) is a grade of paperboard which is typically made of unbleached chemical pulp. |

| Type of paperboard | FBB (Folding boxboard) |

| Description | FBB (Folding boxboard) also referred to as GC or UC. 1. FBB paperboard consist of multiple layers of chemical and mechanical pulp.The top layer is of bleached chemical pulp with an optional pigment coating. 2.A low density material with high stiffness and has a slightly yellow colour inside. |

| Type of paperboard | WLC - White Lined Chipboard with white back |

| Description | White Lined Chipboard refers to: WLC, GD, GT or UD. WLC consists of mult-layers of waste paper or recycled fibers, and two to three layers of coating on the top and one layer on the reverse side. Inside color is grey, but outside surface is white color. |

| Type of paperboard | CCNB (Clay Coated News Back )or WLC (White Lined Chipboard) |

| Description | CCNB consists of white clay coating, recycled newspapers and mixed paper. It has one side coated white color on the top sheet, and another side uncoated grey color as back. So CCNB is available to print full colors on the top sheet. Used in a huge variety of applications because it is reasonably priced and sustainable. |

| Type of paperboard | Art paper |

| Description | also refers to: coated art paper;copper plate paper;copper printing paper.Art papers are one of the highest quality printing papers. The grammage varies from 100 to 230 g/m2. These papergrades are triple coated with 20 - > 40 g/m2/side and have matte or glossy finish. |

| Type of paperboard | Clay Coated & Uncoated- Kraft |

| Description | Unbleached 100% recycled fibres, including a minimum of 60% post consumer waste. Light natural brown in color with flecks from the fibres. Clay Coated Kraft Back (CCKB) has a smooth, white clay coating for high quality printing applied to the top of the sheet.Stronger than CCNB |

SBB(C2S) construction: 1 - Coating 2 - Bleached chemical pulp 1 - Coating Not drawn to scale |  SUB construction: 1 - Coating 2 - Solid Unbleached Board Not drawn to scale |

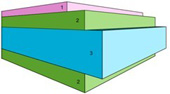

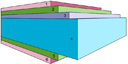

FBB construction: 1 - Coating 2 - Bleached chemical pulp 3 - Mechanical pulp 4 - Unbleached/Bleached chemical pulp |  WLC construction: 1) Two or three coating layers 2) Pulp or white recovered fiber 3) Recovered fibre underliner 4) One or more layers of mixed and/or recovered fiber 5) Pulp or white recovered fiber 6) Back coating |

Please kindly contact us for more details.