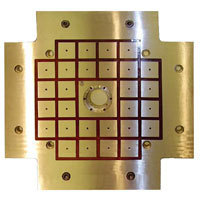

magnetic chuck for injection molding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,DDP,EXW |

| Payment Terms: | T/T |

| Supply Ability: | 100sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | EPPLC series |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Realmagnetic |

| Specification: | As your requests |

| Function: | Fix object |

| Certificate: | CE |

| Export Area: | global |

| Production Capacity: | 100sets/month |

| Packing: | Wooden case |

| Delivery Date: | about 30 days |

Product Description

| Description |

This series magnetic tool, products is used for the manufactory that produces plastic injection produces with Smaller batchs, quicker delivery times and "just in time "delivery force the supplier to more frequent tool/mould change. High performance Tool control Stable-safe-reliable

Using the EPPLC system tool change times of just a few minutes can be achieved. |