Plate Magnet magnetic separator

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 1000000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Structure: | Filtering Machine |

| Function: | Oil Filter |

| Material: | Others |

| Brand Name: | Realmagnetic |

| Production Capacity: | 1000000 |

| Packing: | CARTON |

| Delivery Date: | 2DAYS |

Product Description

| Plate Magnet |

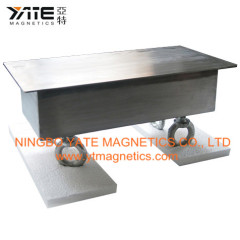

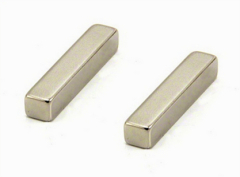

| Plate Magnet is designed to be installed in chute, or in the conveying process. The most displayed position are under conveying material, suspension above the conveyer belt, or installed at the terminal of conveyer. The strong magnetic field will attract and hold the iron tramps when material pass through the plate magnet. Construction: The magnet inside the plate is usually Ferrite or Rare-earth magnet. They are assembled regularly to optimize high-performance. To meet customers' particular requirement, we have multiple designs subject to different product volume and flowing speed. |

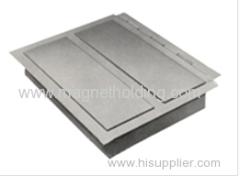

Plain face (PF) |

| Usually, a trap will be added on plate surface, to prevent captured ferrous contaminants from being washed off by oncoming product. A trap face can be either plain shape or tapered step shape on the magnets working surface. |

| Exposed pole (EP) Welded two stainless steel plates on the surface of plate magnet as Polarity. Exposed pole is usually applied to capture ferrous contaminants from relative lower flowing material. | Tapered trap (TT) This trap is a tapered step placed at a position within the north and south magnetic fields that cause captured ferrous contaminants to be drawn to the underside of the trap where they are safely retained, preventing wash off from oncoming product. It is designed for extremely flowing products. | |

| Suspended Plate Magnet It is important to know the allowable suspension height of plate magnet as well as thickness of material burden. This information will help in the proper selection of magnet strength. Another important factor is width of conveyor. Since the magnetic area of | |

| plate magnet should cover the entire width of conveyer. In other words, width of conveyer decides the width of plate magnet. Plate Magnets can be made in various strengths to optimize performance in various depth product streams. The shallower the product stream, the better the separation results will be. | |

| Features: 1. Finishing: either Brushing or Sand blasted 2. Material of shell: 100% SS304 outside. 3. Magnetic strength: multiform magnetic strength standard to choose. 4. Hinge, hang ring, latch etc can be added to the plate for easier installation. 5. Customer designs, specifications can be fulfilled. |

| How to select our products? Please advise us the above necessary information to make enquiry. If you aren't in a position to offer these information, please feel free to contact our engineer and acquaint us with the application environment and material condition. |