Mineral Water Production Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 30 - 50 sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Bottle Blowing Machine, Blowing Mold, Automatic Rinsing Filling Capping Machines, Injection Moulding Machine, Auto Wrap Packing Machine |

Product Detail

| Model No.: | M-3000, M-5000, M-9000, M-12000 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | HAUTEK |

| capacity: | 2000-13000BPH |

| Cooperative Company: | Khushbu Waters, PET packaging |

| RO membranes: | FILMTEC, HYDRANAUTICS |

| pre-filtration: | sand filter, active carbon filter, micro filter |

| sterilizer: | U V, or Ozone |

| Production Capacity: | 30 - 50 sets per month |

| Packing: | PALLET |

| Delivery Date: | 30days to 60days |

Product Description

Based on more than 15 years of professional machinery exporting experience, with rich knowledge of beverage project, bottling technology and bottle making machinery, HAUTEK focuses on high and middle level international market, major in beverage production line design and manufacturing, also supply relative assorted equipment. Supported by strong technical team, we offer high quality machine, good service to customers and give prompt response. We have had success in exporting and installation many beverage production lines abroad.

We manufacture and supply:

We also design and supply for:

Some projects abroad of Hautek: 2001 Nigeria: 200BPH 5Gallon water bottling and 3,000BPH water bottling plant. 2002 Sri Lanka: 3,000BPH carbonated beverage production line. 2003 Maldives: 3,000BPH water bottling line (with seawater desalination) 2004 Sri Lanka: 12,000BPH carbonated beverage production line. 2005 Nigeria: 9,000BPH water bottling production line. 2006 Libya: 2,000BPH water bottling production line. 2007 Angola: 9,000BPH water bottling production line. 2008 Russia: 12,000BPH*2 water bottling plant. 2009 Rwanda: 3,000BPH water bottling production line. 2010 Yemen: 9,000BPH water bottling plant. 2011 Cameroun: 2,000BPH water bottling production line. 2012 Nigeria: 12,000BPH water bottling plant.

|

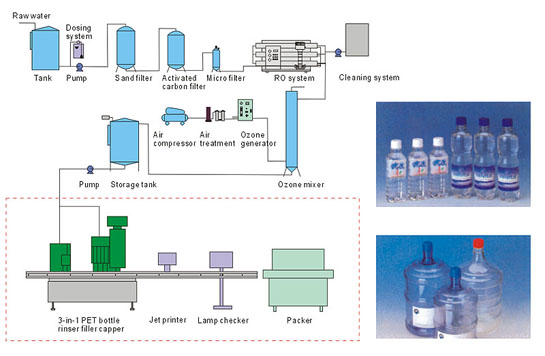

The production line is used for mineral water bottling production. It consists of pre-treatment filtration, RO system, Ozone sterilization system, etc. If for bottling line, filling system, packing system also will be included.

The production line can be adjusted according to different raw water quality, to make much nice taste of product water, to meet the different requirement of bottle water market.

|

Welcome to email us water report, our engineer will check and give expert suggestion, meanwhile we will prepare a quotation file as per your requirement.

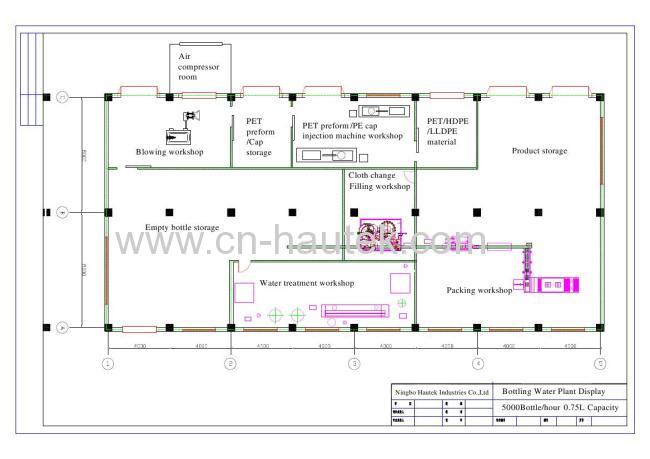

A plant draft can be supplied by inquiry. A techncian team can be sent for machinery installation.

Design Machine installation display for customer: