Equipment of Laundry Wastewater Treatment

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 Set/Sets / Year |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Bottle Blowing Machine, Blowing Mold, Automatic Rinsing Filling Capping Machines, Injection Moulding Machine, Auto Wrap Packing Machine |

Product Detail

| Model No.: | WW |

|---|---|

| Means of Transport: | Ocean, Air |

| Brand Name: | Hautek |

| Raw water PH: | 6.5-9 |

| Turbidity (degrees): | ≤100 |

| BOD5(mg/L): | ≤50 |

| CODcr(mg/L): | ≤150 |

| Suspended solids (mg/L): | ≤500 |

| Anionic synthetic detergents(mg/L): | ≤100 |

| Total coliform bacteria (pc/L): | ≤1000 |

| Production Capacity: | 200 Set/Sets / Year |

| Packing: | Wooden case, Packagesize: 1.5*1.0*2.2m; One 20ft container can load 8 sets. |

| Delivery Date: | 15-20days |

Product Description

Specifications

1.MBR laundry wastewater treatment equipment

2.long service life

3.Professional service

4.high treating effect

1. Product Overview

LWT series laundry wastewater treatment device for reuse is suitable for all types of civil or commercial laundry, with Membrane Bio-Reactor technology. The treated water can reach the standard of non-drinking water for re-use. It can be embedded in places such as road, square, parterre, greenbelt and other places to meet different user requirements.

2. Performance Feature

(1). Simple and Compact structure, make it easy integrate with main building. No noise and unpleasant smell during running, no influence to the surrounding environment.

(2) Less occupied area and able to be buried underground, low operation cost, high quality compliance rate of water output and high stability etc.

(3) It is equipped with an automatic control system, the running process of the entire equipment is under monitoring. All electromechanical devices have alarms and automatic protection system, high reliability of system running and less intensity of labor.

3. Design indexes of input and output water

Serial No | Item | Max. value input | Average | Output standard |

1 | Chroma | 50 | 35 | 30 |

2 | Odor and Taste | Non-unpleasant | ||

3 | Suspended solids (mg/L) | 200 | 110 | 5 |

4 | turbidity(NTU) | 50 | 30 | 5 |

5 | CODCr(mg/L) | 500 | 300 | 50 |

6 | BOD5(mg/L) | 250 | 110 | 10 |

7 | Total bacteria (pc/mL) | - | - | 100 |

8 | Total E. Coli (pc/L) | - | - | 3 |

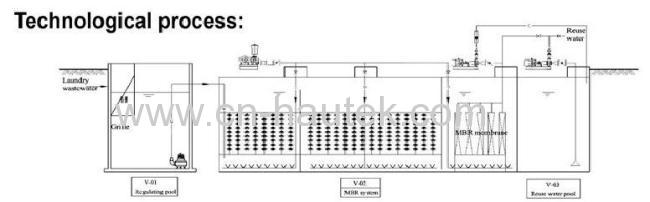

4. Wastewater treatment Technology

LWT series laundry wastewater treatment equipment consists of two stage pools.

The first stage pool is physical treatment process and the second is biological treatment process. The first stage pool made deep, while the second stage pool is shallow.In the first stage pool, to set up the grille well and oil trap to intercept small floating objects and suspended particles in the wastewater before the wastewater flow into the equipment. Membrane bioreactor for the second pool is the combination of membrane separation technology and biotechnology. Membrane module is the core part, The wastewater from regulating pool through the diaphragm which the aperture is 0.2-0.4 μm after being degraded by aerobic microbial in the reactor, to effectively remove the organic matter, microorganism, granular impurities, suspended solids etc in the water. Since the membrane and biological reaction pool integrated into an organic whole that greatly reduce the size of equipment and floor area, and realization of the slight emissions of excess sludge. Usually, the sludge emission is every 1-3 years one time.

Technical Parameter of wastewater treatment equipment

Model | Treated water per day | Reactor Dimension | Floor Area | Power |

(m3/d) | L×W×H(mm) | (m2) | (Kw) | |

LWT-10 | 10 | 750×2000×3000 | 3 | ≤1.1 |

LWT-20 | 20 | 1000×3000×3000 | 5 | ≤1.1 |

LWT-30 | 30 | 1000×4000×3000 | 7 | ≤1.5 |

LWT-50 | 50 | 1500×5000×3000 | 10 | ≤2.0 |

LWT-80 | 80 | 6000×2000×3000 | 15 | ≤3.0 |

LWT-100 | 100 | 6000×2500×3000 | 20 | ≤3.0 |

LWT-200 | 200 | 10000×3000×3000 | 35 | ≤5.0 |

LWT-300 | 300 | 12000×4000×3000 | 50 | ≤8.0 |

LWT-400 | 400 | 12000×5000×3000 | 65 | ≤15.0 |

LWT-500 | 500 | 13000×6000×3000 | 80 | ≤20.0 |

Company Brief:

Based on more than 15 years of professional machinery exporting experience, with rich knowledge of beverage project, bottling technology and bottle making machinery, HAUTEK focuses on high and middle level international market, major in beverage production line design and manufacturing, also supply relative assorted equipment. Supported by strong technical team, we offer high quality machine, good service to customers and give prompt response. We have had success in exporting and installation many beverage production lines abroad.

Some projects abroad of Hautek:

2001Nigeria: 200BPH 5Gallon water bottling and 3,000BPH water bottling plant.

2003Sri Lanka: 3,000BPH carbonated beverage production line.

2003Maldives: 3,000BPH water bottling line (with seawater desalination)

2005Sri Lanka: 12,000BPH carbonated beverage production line.

2006Nigeria: 9,000BPH water bottling production line.

2006Libya: 2,000BPH water bottling production line.

2007Angola: 9,000BPH water bottling production line.

2008Russia: 12,000BPH*2 water bottling plant.

2009Rwanda: 3,000BPH water bottling production line.

2010Yemen: 9,000BPH water bottling plant.

2011Cameroun: 2,000BPH water bottling production line.

2012Nigeria: 12,000BPH water bottling plant.