Seawater Desalinator For Drinking Water

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 100sets/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Bottle Blowing Machine, Blowing Mold, Automatic Rinsing Filling Capping Machines, Injection Moulding Machine, Auto Wrap Packing Machine |

Product Detail

| Model No.: | SW |

|---|---|

| Brand Name: | Huatek |

| Capacity: | 0.1~200m3/hour |

| Salt reject: | >99% |

| Recover rate: | 10~50% |

| Production Capacity: | 100sets/month |

| Packing: | Wood case, or containerized design, |

| Delivery Date: | 15days~20days |

Product Description

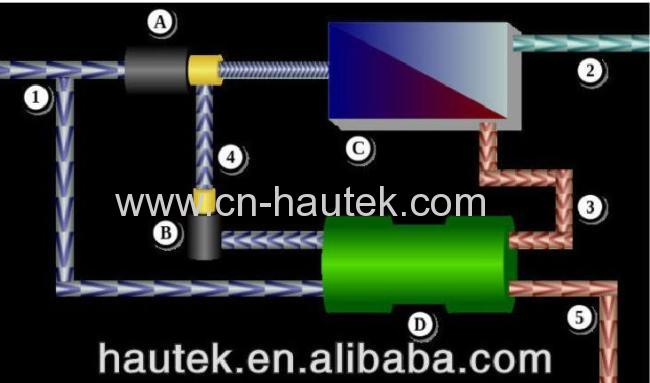

Sea water reverse osmosis (SWRO) is a reverse osmosis desalination membrane process that has been commercially used since the early 1970s. Because no heating or phase changes are needed, energy requirements are low, around 3 kWh/m3, in comparison to other processes of desalination, but are still much higher than those required for other forms of water supply, including reverse osmosis treatment of wastewater, at 0.1 to 1 kWh/m3. Up to 50% of the sea water input can be recovered as fresh water, though lower recoveries may reduce membrane fouling and energy consumption.

Desalinator by reverse osmosis membrane, based on different raw water quality, we have different membrane & high pressure pump. We have enough technology to deal with different raw water, capacity from small to big.

1. Raw water: Seawater (TDS: 10000~55000ppm)

2. Salt rejection: ≥99%;

3. Design: One stage or two stages, based on product water requirement;

4. Full-automatic controlled or Semi-automatic controlled;

5. Compellent automatic freash after system stop working;

6. Different pre-filter to suitable different raw water condition;

7. Capacity: 0.1~200m3/hour

8. Product water reach WHO drinking water quality limited, or special design to reach client required.

Company Brief:

Based on more than 15 years of professional machinery exporting experience, with rich knowledge of beverage project, bottling technology and bottle making machinery, HAUTEK focuses on high and middle level international market, major in beverage production line design and manufacturing, also supply relative assorted equipment. Supported by strong technical team, we offer high quality machine, good service to customers and give prompt response. We have had success in exporting and installation many beverage production lines abroad.

Some projects abroad of Hautek:

2001Nigeria: 200BPH 5Gallon water bottling and 3,000BPH water bottling plant.

2003Sri Lanka: 3,000BPH carbonated beverage production line.

2003Maldives: 3,000BPH water bottling line (with seawater desalination)

2005Sri Lanka: 12,000BPH carbonated beverage production line.

2006Nigeria: 9,000BPH water bottling production line.

2006Libya: 2,000BPH water bottling production line.

2007Angola: 9,000BPH water bottling production line.

2008Russia: 12,000BPH*2 water bottling plant.

2009Rwanda: 3,000BPH water bottling production line.

2010Yemen: 9,000BPH water bottling plant.

2011Cameroun: 2,000BPH water bottling production line.

2012Nigeria: 12,000BPH water bottling plant.